Abstract

The recent lack of a skilled labour force is a high risk for the economy in Vietnam. Within ASEAN, “Vietnam ranks in the lower half of human resources development” (EuroCham 2014, 31). Therefore, according to the Organization for Economic Co-operation and Development (OECD), “reforming training and education to better meet demand for skilled labour” is one of Vietnam’s key challenges for the medium-term (EuroCham 2014, 31). For the long term, TVET institutions have not had connections with industry. This causes a gap between the need of a labour force, which comes from industry, and the quality of the labour force who are trained in TVET institutions. The best solution for solving this gap is through the enhancement of Work-Integrated Learning through cooperation of TVET institutions, companies, and universities.

Training-on-the-job has already existed in parallel with training at vocational schools in Vietnam for decades. However, such training has not yet formally become a part of TVET. Is a Vietnamese “DUAL IN TRAINING” model for TVET, in which vocational learners can learn both in school and within real work situations, available? And how can we improve the quality of training a TVET teacher? The answer will be introduced in this paper, which covers the result of a field study which examined on-the-job training at a series of companies within two months. This field study utilized a combination of both qualitative research methods and analysis of case studies, which were observed during the last field trip. In addition, a best-practice-example, conducted at University of Technology and Education in Ho Chi Minh City by using Principle CDIO (conceive, design, implement, and operate), will be presented.

Key words: CDIO, training-on-the-job, WIL, skilled labour force

1 Introduction – the importance of WIL in Vietnamese Vocational Training System

1.1 Introduction

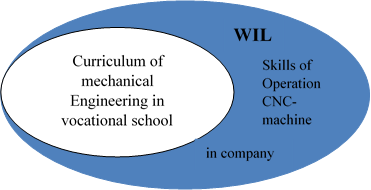

The 2014 World Bank Vietnam development report was titled “Skilling up Vietnam: Preparing the workforce for a modern market economy” and was published in November 2013. This report emphasized the need of job-specific technical skills in the Vietnamese workforce, not only for blue-collar workers but also for white-collar workers (World Bank 2014, 16). During a field trip to a company in the field of plastic moulding, through qualitative interviews with three managers and fourteen workers who worked as CNC-operators, the implications of the World Bank report can be clearly observed. Most workers needed to be trained when they entered as new employees in the company, needing at least three to six months to adapt to their job. Moreover, so that these employees could do their tasks confidently, they worked as CNC-operators for nearly one year. This is true not only in this specific plastic moulding company but also in three other companies, which have also been visited. Companies in Vietnam typically have to train their new employees, and they spend a lot of time and money to do so.

New workers at the plastic moulding company follow an experienced employee to learn how to operate CNC machinery for making parts of plastic moulds. Most interviewees recognized that they cannot operate CNC-machine at the beginning when they entered the company, admitting that they needed instruction from another skilled worker who is considered a master CNC-Operator. New employees were trained on how to operate a CNC-machine, how to position a working part in the machine, how to load a program, and how to make a macro program in order to process a work-part. These employees have not been trained in these essential skills, which a CNC-operator should possess, although they had graduated from a vocational school in the field of mechanical engineering. How does this happen?

The answer can be found through interviews with workers, who claim that they had not operated a CNC-machine when they studied at vocational school. Most schools have only one or two industrial CNC-machines for training. This means that training usually involves a teacher modelling how to set up the machine, position a work-part, load a program etc. while trainees merely observe. This happens also with apprentices from vocational school. In order for the company to avoid accidents and damage to the machinery, these apprentices usually only observe how a CNC-machine works, though they may have some opportunities to do some simple tasks such as picking up a work-part. Sadly, there has never been a formal agreement between vocational schools and companies regarding student training and qualifications prior to graduation. Moreover, companies do not know the learning outcomes and demands of apprenticeship programs.

WIL in Vietnam can be classified into two groups:

− WIL can be understood as a way of teaching during the apprenticeship before graduation. The apprenticeship only lasts for two or three months, and there is no agreement between companies and vocational schools about the relevant content or demands during this apprenticeship. This depends totally on the companies where the apprenticeships take place.

− WIL can be understood as adaptive training after entering a company. In this case,

“training-on-the-job” or “adaption training” are synonymous terms for WIL.

1.2 Recommendations and needs for WIL concepts in Vietnam

WIL is already existing and taking place in vocational school systems in Vietnam. WIL can be integrated in the curriculum and during training, focusing on learning theory and practice in vocational schools and apprenticeships. Some occupations, such as banking, tourism or economic careers, have done this very well. Unfortunately, in the mechanical engineering training course, especially CNC careers, it is very difficult to make WIL come true. The existing course has just now focused on training skills for operating conventional machines such as lathe machines and milling machines. In the mechanical engineering curriculum, some time is dedicated to learning CNC-machinery but not enough time. At the same time, vocational schools cannot be equipped with enough CNC-machines for the demands of training, and schools also do not have enough skilled trainers. One solution to this pressing matter involves vocational schools sending their students to apprenticeships in order for students to properly learn CNC machine operations. These kinds of apprenticeship are intensive training periods or an extended training time outside of school. Ideally, these apprenticeships would clearly define their learning outcomes to future employers so that afterwards the trainees can control and reflect on their achievements. Moreover, these apprenticeships would need to provide insurance to protect trainees from any health or financial burdens related to job-site accidents.

The current situation in vocational training in Vietnam is similar to Germany’s situation 150 years ago, when the demand for a trained workforce was too high and the vocational school system could not satisfy this requirement. In 1769, Margrave of Baden was worried that skilled workers such as stonemasons, bricklayers, and tilers would not have enough qualifications to effectively and independently do their job. Many companies tried to train their workforce by themselves (Jongebloed 1998, 260). This is currently happening in Vietnam. But the nature of training on the job is very specific and narrow. The trained workers can only effectively complete tasks specific to the company in which they were trained. The workers do not have enough competencies to face the working world, which changes day after day. This gap was discussed in an article by Andrew Trounson, University of Melbourne with the title “Narrow Training Sells Students Short” (Trounson 2017). An occupational profile for specific occupations can minimize this gap because this job profile can provide guidelines for training courses in vocational schools and companies. Such a profile would comprise of knowledge, skills, and attitudes of specific jobs, which learners have to master before graduation. Therefore, these profiles can be used to build curriculum for training, and this curriculum can be shared with vocational schools and companies.

2 Work-readiness and practical learning as key factor in training VET-teachers

2.1 The CDIO-concept and its usability for VET-teachers

During the field study, one manager at an electronic company was asked “What do you expect from your engineers?”

The manager answered that it is very important that an engineer can use Eagles software to design a printed circuit small enough to be suitable for small drone that the company intends to produce. Therefore, a student who has worked on this sort of project in the course of their training and education will easily and effectively overcome routine challenges in the workplace. Through this interview it was recognized that some of the most important skills that a company demands from an engineer involve using knowledge of technical fundamentals to solve complex problems and to design new products.

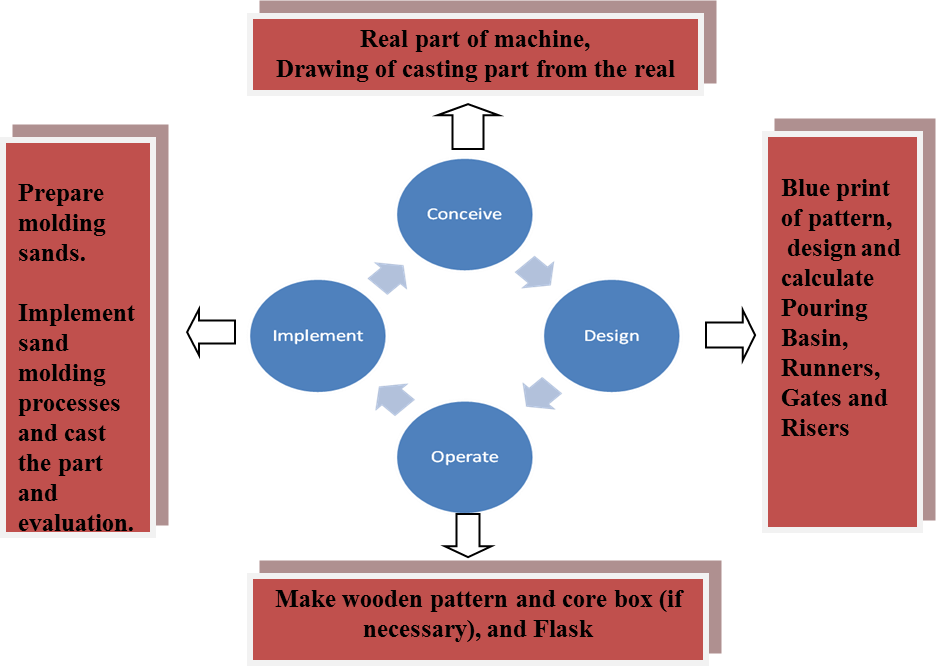

The reason why CDIO is a suitable concept for training VET-teacher is “because it provides the natural setting in which to teach key pre-professional engineering skills and attitudes.” “The essential feature of the CDIO approach is that it creates dual-impact learning experiences that promote deep learning of technical fundamentals and of practical skill sets” (Crawley, Malmqvist, Ostlund, Brodeur, 3). CDIO comprises of four words: conceive, design, implement, and operate. It is a concept which was originally formulated by Massachusetts Institute of Technology (MIT) in Cambridge, Massachusetts. CDIO’s philosophy emphasizes the “essential features of a modern engineering education – excitement about what engineers do, deep learning of the fundamentals, skills, and the knowledge of how engineers contribute to society” (Crawley, Malmqvist, Ostlund, Brodeur, 3) to teach “processing technology”, which was traditionally conveyed only in a theoretical manner. The lecture comprises of three parts: foundry technology, forming technology and welding technology. “Foundry technology” is conducted in seven weeks. With experiments on casting processes in the laboratory, “foundry technology” works as a practical addition to the typical theoretical lecture, in combination with applications of CDIO concepts as a way to lead students to learn not only with their brains but also their hands and their hearts. The project “foundry a work-part” belongs to the course “foundry technology” and was implemented parallel to theoretical lecture. (See table 1). This innovation comes from the program HEEAP (Higher Engineering Education Alliance Program), which was initiated by Intel, USAID (U.S. Agency for international Development) and ASU (Arizona State University).

Table 1: Project tasks are designed parallel to contents of the course

|

Tasks |

Syllabus |

|

|

Drawing of the part (from the real part) |

Week 1 |

Chapter 1: History and Definition of Foundry Technology |

|

Drawing of casting part |

||

|

Blue print of pattern (from the given part) |

Week 2 |

Chapter 2: Casting design |

|

Make wooden pattern and core box (if necessary), and Flask |

Week 3 |

Chapter 3: Patterns – Their Function in Sand Casting |

|

Design and calculate Pouring Basin, Runner, Gate and Risers, |

Week 4 |

Chapter 4: The feeding of casting |

|

Prepare molding sands. |

Week 5 |

Chapter 5: The moulding material: properties, preparation and testing |

|

Implement sand moulding processes and cast the part |

Week 6 |

Chapter 6: The manufacture of sand castings |

|

Evaluation |

Week 7 |

Chapter 7: Typical Molding Problems |

2.2 An example of CDIO for training VET-teachers

At the beginning of the course, the class is divided into groups. Each group comprises of four to six students who are assigned a real part to a machine. (Fig. 2) Then each group recieves list of tasks (table 2). Their first task is to develop a technical drawing from the part. In order to develop a technical drawing, students have to use basic measuring tools such as a vernier caliper to measure a real piece of machinery and to apply their knowledge of development in a technical drawing (fig 3).

The following table is a list of tasks that were given to every group on first day of the course. This table contains weekly deadlines (date) for tasks and student evaluations (result).

Table 2: Tasks of the foundry project

|

Tasks |

Date |

Result |

|

Drawing of the part (from the real part) |

||

|

Drawing of casting part |

||

|

Blue print of pattern (from the given part) |

||

|

Make wooden pattern and core box (if necessary), and Flask |

||

|

Design and calculate Pouring Basin, Runner, Gate and Risers |

||

|

Prepare molding sands |

||

|

Implement sand moulding processes and cast the part |

This project ensures that students can apply what they have just learned in class to real-world situations (Table 1). In order to engage student passion, the lecture does not utilize the traditional “chalk-and-talk-teaching”. Students use knowledge of technical fundamentals, gained not only from the foundry technology course but also from past knowledge, to solve problems. Therefore, the project is realized as a process: conceive, design, operate, and implement (Fig. 4)

The advantage of this project is the experience knowledge that is gained during the processes which students perform in the lab at the end of project. With these experiences, students can apply and compare theoretical knowledge, (which they have learned in class before) with steps and results in practice. For example, some experiments might deal with how to mix and check mixtures of sand for casting (Fig. 5), how to prepare patterns to make moulding, or how to take patterns out of mould.

The students are encouraged to apply and reflect on what they have learned and apply this knowledge to new and unexpected problems. When these problems are solved, they have more confidence in their learning abilities and in their skills as future professional engineers.

2.3 The project method and its effects towards the development of professional competencies

In practical courses, such as in a welding course, students are required to complete tasks in order to finish their course’s work (for example: butt joint, lap joint, tee joint in positions 1G, 2G, etc.) This method does not engage student interests during the course and does not provide target-orientated support to form skills regarding professional competency and soft skills. So during the project, there was a didactical change. The class was divided into groups. Each group could develop their ideas according to the task given to them, e.g. drive-wheel-bicycle, pinwheel for garden decoration, etc. Those ideas were then developed within self-organized projects.

During the project, students have opportunities to work with many types of equipment, not only welding machine, but also hand-grinding and cutting machines.

Throughout the practical course, students gain not only professional competencies but also soft skills such as problem-solving. Students also developed negotiation skills, teamwork skills, and presentation skills.

3 Conclusion

The integration of experimental tasks in project methods is a very effective method for enhancing student motivation. Students learn not only theoretical knowledge but also practical skills. Students are driven by passion, curiosity, engagement, and dreams. These methods give students motivation to learn not only for examinations but also to gain knowledge for future careers. We do not know what awaits our TVET-students in the future. We do, however, know some competencies that will help them to overcome challenges, to achieve new knowledge, and to build professional proficiency. The integration of experiments in project methods helps students to anchor knowledge effectively and provides more practice to support professional competencies—not only now but also in their future professional life. Most importantly, these practices give students “readiness to be an engineer”.

References

EuroCham (2014): Trade/Investment Issues & Recommendation, 18-31.

Jongebloed, H.-C. (1998): Komplementarität als Verhältnis: Lernen in dualer Struktur, in: ders. (Hg.): Wirtschaftspädagogik als Wissenschaft und Praxis – oder: Auf dem Wege zur Komplementarität als Prinzip (Moderne der Tradition, Bd, 1), Kiel: bajosch Hein, 259-286.

Trounson A. (2017). Narrow training sells students short, University of Melbourne. Online: https://pursuit.unimelb.edu.au/articles/narrow-training-sells-students-short, (retrieved 06. March 2017).

Vo Xuan Tien (2014). Enhancing Student Motivation in Foundry Technology using Active Learning and CDIO Practices. In: Vietnam Engineering Education Conference 2014; March 25-26, 2014, Ho Chi Minh City, 39.

Vo Xuan Tien (2014). Project-Based Learning: Best practice to implement CDIO-Principle – Experiments through teaching Foundry Technology at University of Technology and Education Ho Chi Minh City. In: CDIO Conference 2014; December 12, 2014, Ho Chi Minh City, 22

Vo Xuan Tien (2015): “Introduction to Engineering” Course – a Catalyst for Innovation in Engineering Education and Blooming Student’s Creativity, In: Vietnam Engineering Education Conference 2015; March 16-17, 2015, Danang City, 27-28.

World Bank in Vietnam (2013). Vietnam development report 2014- Skilling up Vietnam: Preparing the workforce for a modern market economy.

Citation

Tien Vo, Xuan (2017). WIL in Vietnam and Best practice example of CDIO at HCMC University. In: TVET@Asia, issue 9, 1-14. Online: https://www.tvet-online.asia/issue9/vo_tvet9.pdf (retrieved 30.06.2017).