Abstract

What is required of TVET practitioners today is not merely the understanding but the application of ‘Work process knowledge’, which is considered a major training focus. All functional areas play vitally and are interlinked and inter related. The concept of work process knowledge has gained importance for transformation in nature (Boreham 2002). The passive connection between academia and industry ought to be replaced with an active and strategic engagement. To achieve the transition, it is essential to shift the perspective to a ‘many to one orientation’, enabling the trainees with multiple information resources, of which only one is the assessor. Knowledge creation becomes integral to new ways of organizing work. It is very interesting to apply the work process based curriculum in the Fashion & Textile design sector in Pakistan. A case study approach is attempted to analyse the application process, impact and benefits of applying the work process based curriculum for Fashion & Textile design sector at STEP Institute of Art, Design & Management. The potential gains are high and it promises to benefit multiple stakeholders, including the trainees, the faculty, directly linked employer, industry and it leads to financial and industrial benefits at macro level too.

Keywords: Work process based curriculum, Step model, textile industry

1. Literature Review

In order to understand the importance of work-process based curricula, one needs to understand the concept of work-process knowledge. It can be described as an employee’s knowledge about the organization as a whole, including production process, human resources, labour department, operations and marketing processes etc. Each department plays a vital role in the prosperity of the organization hence, all departments and processes are interlinked and inter-related. All of this information goes far beyond what is needed to support a single job in this respect; the concept of work-process knowledge has gained importance for transformation in nature (Boreham 2002). “Work process based curriculum development process itself is called the work process co-production of vocational curricula” (Bernard 2000). The purpose is to remove irrelevant theory from vocational subjects and to add theoretical and practical content related to prospective work roles. This can only be achieved by attaining close collaboration between vocational training institutes and related industry to give a new direction to VET sector. Although, the conventional system is not completely ineffective and it strives for a gradual improvement, we need radical changes in curriculum development. An analysis of education and management literature and practice suggests that we move from deterministic systems to goal-seeking systems (Betts 1992). To achieve this kind of transition, it is essential to shift the perspective from a one-to-many direction to a many-to-one orientation. In VET, for example, this means a shift from viewing education as a system in which an assessor delivers information to many students towards a system in which many information resources are available to a student, of which only one is the assessor. This shift can be categorized by moving from an emphasis on teaching to an emphasis on learning.

From the perspective of systemic change, the implications of this idea are huge. The new designs will include an increasing number of the elements such as outcome-related standards, benchmarks for each standard against which to measure individual and programme progress on a continuous basis, assessment based on performance compared to benchmarks, self-assessment, triangulation (use of multiple forms of assessment by multiple assessors to increase the validity and reliability of feedback), immediate intervention, generative learning (Wittrock 1974), reflective practice (Schön 1987), varied learning structures (self-directed, one-to-one, small groups, lecture, field study, apprenticeships, mentoring), year-round schooling, assignment to learning groups based on individual performance, intact teams working over an extended period of time (more than one year) to achieve a common goal, increased sources of information via telecommunications from school and home, using cooperative learning structures, from video and optical media, supported by fully integrated, interactive computer-assisted instruction through a variety of electronically linked community resources (home, school, work, libraries, recreation centers, health care facilities), digitized student information and instructional resources, “electronic books”, multilingual resources, multimedia delivery (sound, graphics, and/or text options), tightly integrated curriculum, instruction, and assessment, hierarchy of small, six-to-eight person, self-sufficient, semiautonomous teams (sub-systems).

These are not completely new elements; however, a designed system has not been made that incorporates all these elements. The purpose is for developing vocational curricula for flexible and innovative workplaces where knowledge creation is an important part of the work. But as we move from the Taylorist era into the knowledge-based economy, knowledge creation becomes integral to the new ways of organizing work. Learning becomes the new form of work, and then new frames of reference and concepts are needed to underpin vocational curriculum development.

The German case study of “Volkswagen” (Boreham 2004) could be taken as an example and a model of contemporary learning & practices that support the idea of work process based curriculum. The key features of their approach used a model of the work process as the curriculum framework, co-producing the curriculum using integrated teams of staff from the vocational school and the workplace, and combining the different knowledge resources of the vocational school and the workplace into a single activity system designed specifically for “Industry Mechanics”. This paper attempts to further discuss this approach by presenting a pilot project initiated at STEP Institute of Art, Design & Management, Lahore, Pakistan. The Fashion & Textile design sector is chosen as case study, which is rapidly emerging and becoming widely accepted vocational qualification in Pakistan. Initially work process curriculum development is applied in Fashion & Textile design area to study the impact on related stakeholders including academia, industry, assessors, students etc. A recent United Nations Population Fund report makes the claim that out of 200 million people, 63 per cent of Pakistan’s population comprises of youth. Of these, 58.5 million are 20-to-24-year olds while 69 million are under 15 years of age (Ali & Hafeez 2017). Immediate post training employment remains one key aspiration and motivation for the young TVET trainees in Pakistan. The work process based curriculum model promises to provide the solution and it will further enhance the scope of TVET in the country.

The Fashion and Textile industry in Pakistan is emerging with new trends and practices, which is expected of them by the international counterparts. Being an eminent member of the global textile fraternity, it has a vital role to play. The Textile industry in Pakistan is the largest manufacturing industry in country. Pakistan is the 8th largest exporter of textile commodities in Asia. Textile sector contributes 8.5% to the GDP of Pakistan. In addition, the sector employs about 45% of the total labour force in the country (and 38% of the manufacturing workers). Pakistan is the 4th largest producer of cotton with the third largest spinning capacity in Asia after China and India and contributes 5% to the global spinning capacity. At present, there are 1,221 ginning units, 442 spinning units, 124 large spinning units and 425 small units which produce textile (Pakistan bureau of statistics 2017). Pakistan‘s Fashion & Apparel industry is also becoming an important dimension of the country’s economy due to its export potential worldwide. The significance of fashion industry is being realized in view of its huge potential for future expansion as well, where both the need of building local brands as well as contributing in the global fashion industry is emphasized.

2. Work process based Curriculum application at STEP Institute of Art, Design & Management

STEP was established in the year 2002 as an independent pro TVET institute with the aim to create and explore maximum possible channels and resources for vocational education in the country, and to stimulate a holistic approach to the TVET sector. STEP is an effort to create a model system that symbolizes an astounding vocational learning environment. It is focused to build global competences while catering to the local needs. These opportunities must be in line with the global needs to create a sustainable demand of our local professionals, trainees, graduate designers and technicians.

In Line with the vision of STEP, it initiated its academic facility with the name of Institute of Art, Design & Management (IADM) in 2003 that offers various internationally recognized professional and vocational qualifications, under guidance and accreditation of several international awarding bodies. IADM is working as a recognized learning center for Pearson (Edexcel), UK to provide vocational (level 3 – 7). Faculty of Art & Design is the largest faculty at IADM and Fashion & Textile design are the flagship qualifications, therefore, this paper is written to focus the application, process and impact of work process based curriculum development for Fashion & Textile design courses.

The rapidly changing industry demands and requirements are becoming more advanced as well as skills oriented. This calls for a further competent workforce, which is trained and smart enough to provide every day solutions at work. In order to remove the blockade, the Art & Design faculty at STEP strongly felt the need of upgrading the knowledge and skills of trainees in vocational context. The curriculum structure as well as the content was thoroughly reviewed based on the twofold objectives; one: meeting the needs and expectation of industry being the employer, and two: to enable trainees for quick employability and efficient performance as employees.

2.1 Steps for Review and Development of Curriculum

The steps that were followed during the review & development of curriculum included:

2.1.1 Survey for Curriculum Review

The faculty planned for the industry surveys under guidance and direction of its Industry Advisory Group (IAG). Part of the research activity was to study and closely observe the set of work related tasks that are expected to be undertaken by entry level designers and new hires in fashion & textile industry. The research team was also designated to record their observations and on-floor conversations with managers and workers to identify the gaps in existing curriculum.

2.1.2 Analysis

A detailed analysis was conducted on basis of the preliminary industry based research, observations and feedback of employer organizations. The primary objective at this stage remained, the clearest understanding and expectation of industry from fresh fashion and textile designers. The various stages of industry processes and work flow were also analyzed.

2.1.3 Post Research Industry Engagement Exercise

The post research exercise of engaging industry proved extremely successful yet it encountered multiple challenges at initial stages. It was difficult to bring various levels and types of industry players on one page. Time availability, clash of ideas with reference to specific nature of employment sectors and roles leading to heterogeneous set of expectations were top of list. This was obvious since the prospective cluster of employers in Fashion & Textile sector are diversified in terms of their organizational scope and nature, such as retail, wholesale, production units, buying houses etc. The IAG (Industry Advisory Group) members actively played their roles for resolving most of these challenges and creating harmony among varied industry representatives to formulate the desired training curriculum.

2.2 The STEP model for developing work process based curriculum

It is highly significant for the vocational education providers to not only know the various work processes of related industry or sector but to also upgrade their knowledge of all contemporary local and international practices. It is unfortunate that the vocational sector in Pakistan lacks behind their expected knowledge of changes that have occurred during the last decade. Digitalization has taken over almost all fields of life. The Fashion and Textile industry today needs experts in digital fashion, equipped with the above-sketched knowledge and competences. The conventional curriculum is not adequate to suffice the purpose. Although it allows trainees to excel well in stages until design development but what is lacking is the actual knowledge of what is expected of graduates on job from concept to the end product. The aspiring graduates create their wonderful collections and are capable of presenting their theme based / experimental outfits. However, they lack the very meticulous and detailed hands-on experience of all the various stages that are required for producing hundreds and thousands of design products for design houses and industry. Majority of graduates wish to work for production houses who are exporting the products globally and prestigious brands like Zara Men, Zara Girl, Zara Woman, Adidas, GAP, Nike will not compromise on the set quality standards and finishing requirements. The various steps involved in the industry include conceiving the Product concept, Research, Product design development, Research & development of final design, CAD, CAM, Prototype testing, Manufacturing, Assembly, Feedback and testing, Product development and Final product. At STEP, the faculty is able to create a model that now allows the trainees to not just focus on developing their final collection but also be prepared at expert level while dealing with huge production targets. This has been achieved by incorporating the various stages and processes that are essentially required to perform efficiently at work. One most important tool that helped the faculty in developing the curriculum is the inclusion of Tech Pack training in the curriculum.

2.3 Inclusion of Tech Pack training in Fashion & Textile design curriculum

Tech Pack is an informative sheet that designers create to communicate with a manufacturer. It elaborates all the necessary components needed to construct a product or outfit, including all the measurements, materials, colors, trim, hardware, grading, labels, tags, etc. A tech pack can go by many different names, such as technical specification, specification pack, spec pack, BOM (bill of materials) or GWS (garment work sheet). Essentially it is a document required by and referred to garment technicians and designers who make the garment patterns and manufacture the clothes. No industry or production unit in Pakistan could work with international brands and companies for manufacturing garments without using the tech pack.

The conventional graduate would start knowing its practical usage not at school but at factory after being employed, which frustrate both the trainees and the employer. The industry requires its prospective employees and designers to already have the knowledge of all work processes during their training in order to compete in the market and fully optimize all their resources. The incorporation of Tech pack usage and working in the curriculum is greatly helpful to our current trainees who are not only understanding the step by step approach of the production process, as done in industry but they are also proving to be highly efficient human resources. It’s simple and fast tool for fashion designers to develop faster, track all styles, work together with all connected departments and meet the employers‘ expectations. The Importance of Tech Pack design is a must-do step of apparel production. Tech pack design is related to pattern design, sample development and apparel production. It also helps determine the costs of the product since it encompasses all the components of the style and gives the estimate of the costs that will be incurred during production and hence excelling the value for their employers.

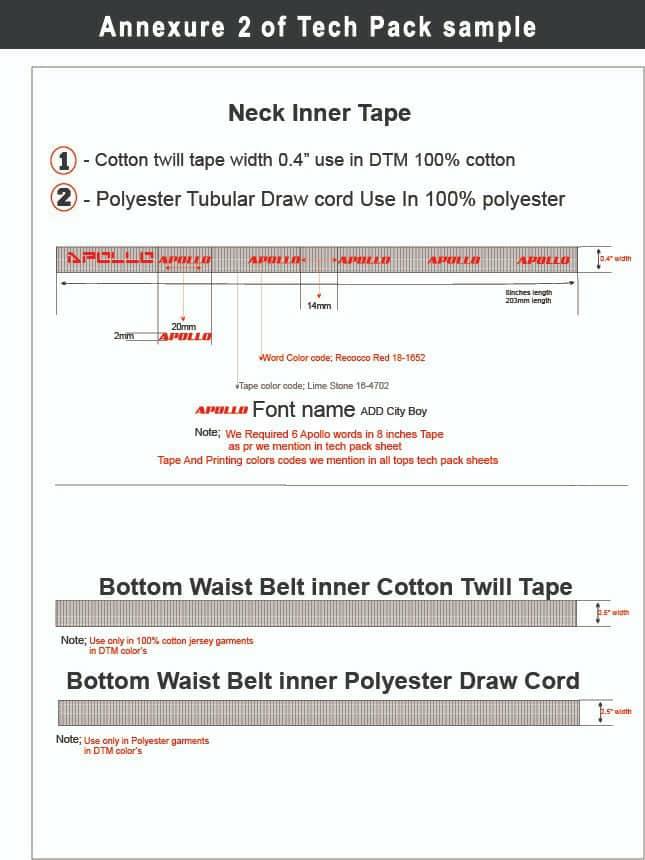

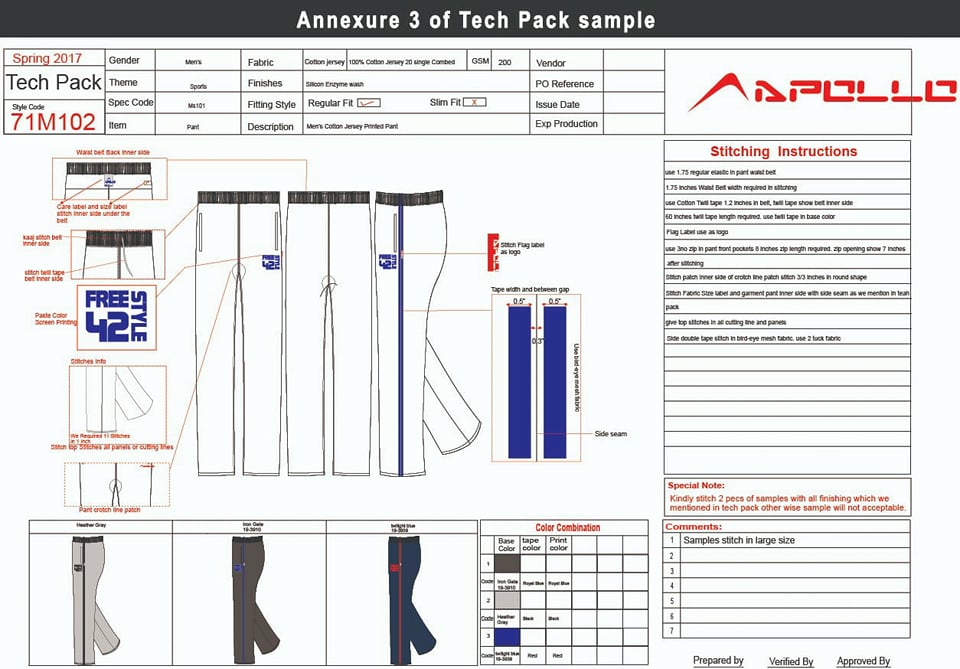

Few sections of the tech pack sheet are enclosed in annexure (given at the end) to give an understanding about how it helps the trainees in learning and performing according to the expected work processes. Annexure 1, for instance, explains the way codes are generated and implies the basic labelling of any production, including the season, the sub category, gender and style codes. It lays the initial planning process before the production process starts. The annexure 2 shows the various measurements for different parts of the product. It greatly helps in scientifically optimizing the fabric usage. The 3rd annexure demonstrates the summary of outcomes from all processes for the production. It gives clearer instructions for every process of production ranging from the selection of fabric to sizes, accessories, stitching, coding, finishing and packing.

The inclusion of Tech Pack training module not only as one subject but its amalgamation in all technical courses including Pattern designing, Pattern drafting, Production methods, and Realizing a collection has been a pioneer step towards developing our curriculum on work process based approach. It is highly promising because it allows the trainee to already get fully acquainted and familiarized with what they are going to perform at work.

Other than the inclusion of Tech Packs, following measures have also been employed as result of industry engagement and dialogue on developing work process based curriculum.

1. The fashion and textiles industry is now focusing on digital designing in semi-formal, casual and party wear. This was incorporated in our curriculum as two additional units (courses), to be offered during the last two semesters in Fashion & Textile design qualifications.

2. In formal and semi-formal category, industry also focuses on hand-made embellishments and creative fabric surface designing. This need was catered in the curriculum in form of workshops on ‘Adda work’ (which is the traditional Pakistani technique that involves multiple craftsmen to manually do the embroidery and embellishment on unstitched cloth. The fabric is spread and tightly placed with the help of a large 8X10 feet or more wooden frame, allowing 4 to 5 people (or more, subject to the size of adda frame) to work on it at one time). Very sharp supervisory skills are needed for trainees to avoid fabric and time wastage, maximum utilisation of embellishment material, enhancing design quality and finishing.

3. The previous curriculum, not only at STEP but generally in all other design institutes as well, focuses more on design development skills and comparatively lesser emphasis on developing technical skill. The industry needs design graduates who are acquainted with and skilled in various aspects of production i.e. sketching, tracing, punching, colour scheming and design transfer etc. These technical elements need more concentration and hands-on training method. As a result, two different major assessments are now incorporated. Design students are now creating two collections during their four years of studies. The third year collection is more focused on the design development area and the last year collection makes them expert in technical skills other than developing designs.

4. There is strong need of expert level knowledge of the Wilcom software other than the basic design software’s (including Photoshop, Illustrator and Corel Draw). An extra course to teach Wilcom software is now added in the curriculum. This also enhances the institution’s commitment to acquire and develop the work process based curriculum since graduates in the past used to learn this software on the job instead of doing it during their studies.

2.4 Challenges, Sustainability and Impact of the model

The faculty of Art & Design at STEP Institute of Art, Design & Management initiated the process of reviewing and developing its curriculum for the four vocational undergraduate programs; Fashion Design, Textile Design, Interior & Architecture Design and Graphic Media Design. The process was started last year in August and it got boosted after the active involvement of its Industry Advisory Group. The preliminary research, industry visits and on the job observations were recorded and finalized in September last year. The first time application of the revised curriculum focused on work process was done in the fall academic semester: October 2017 – March 2018. Despite the very promising results, it faces numerous challenges for the sustainability of this model. It requires a constant connection with industry. Some industry players have been very helpful in allocating time and resources for this research investigation but this needs to be adopted and advocated at macro level. The local chambers of commerce & industries could help in motivating the industry players for partnering up with vocational institutes to work as bigger teams for understanding and suggesting the work process based curriculum. This will lead to a win-win scenario for all stakeholders.

The apex body at national level in Pakistan (National Vocational & Technical Training Council NAVTTC) could further raise the spirit by directing vocational education providers to align their curriculum with work process approach.

Although the current face of Fashion & Textile design sector is getting heterogeneous and rapid inclusion of both genders is opening progressive horizons, still it remains hindrance for some female trainees to experience the highly male dominating production units. Training on soft skills, attitude & aptitude and counselling can help encountering this.

Availability of the teaching resources is another challenge in Fashion & Textile design sector, specifically for this purpose. The work process based curriculum approach requires trainers to continuously upgrade their skills and knowledge of industrial practices. At STEP, the faculty had to hire industry technicians and software experts who are not conventional teachers but they are the best people to train in accordance with industry work processes. These are additional to the full time teaching resources and therefore, the application of this model raises financial liabilities in the beginning. Whereas in long run, this is profitable and an opportunity for TOT as well.

The initial impact is very positive and encouraging. The trainees who finished their last semester, studying the revised work process based curriculum, are far more skilled and ready to go for immediate employment because they are very likely to effectively take on the job tasks. There has been a practice in industry to hire fresh graduates and if not fully acquainted with the job and work processes, designers are hired as interns and either unpaid or only paid stipends until they get trained on job. The work process based curriculum is highly likely to support the trainees as promising employees who will not need months of on-job training. Our previous design graduates, who are already working in fashion & textile industry for over 6 months have lesser knowledge of the generic production processes, comparing to the recent ones who learnt and applied the new curriculum. Addition of Tech pack specifications has remarkably supported this approach. The additional augmentation to the traditional skills set has added more employment chances and multiple job opportunities. This approach has enabled our fashion & textile trainees to gain skills and expertise related to technical drawings, specification of garments, patterns, prototype and sample creations and much better quality management of production.

The biggest benefit of work process based curriculum is the synergy between industry and academia. Graduate designers and employer manufacturers work efficiently together if they have the same expectations from the beginning of their relationship. In an ideal world, every employer organization would require its employees to explicitly understand all their operations and functions and this could be attained by developing and applying the work process based curriculum.

Annexure

Figure 1: Annexure 1 of Tech Pack sample

Figure 2: Annexure 2 of Tech Pack sample

Figure 3: Annexure 3 of Tech Pack sample

References

Bernard, F. (2000). Forschungsmethodische Lösungsansätze zur Differenzierung und Integration von technischem Wissen. In: Pahl, J., Rauner, F. & Spöttl, G. (eds.): Berufliches Arbeitsprozesswissen. Ein Forschungsgegenstand der Berufsfeldwissenschaften. Baden-Baden: Nomos, 149-158.

Betts, F. (1992). How Systems Thinking Applies to Education, Educational Leadership. Online: http://www.ascd.org/publications/educational-leadership/nov92/vol50/num03/How-Systems-Thinking-Applies-to-Education.aspx (retrieved 28.6.2018).

Boreham, N. (2002) Work Process Knowledge, Curriculum Control and the Work-based Route to Vocational Qualifications. In: British Journal of Educational Studies, 50, 2, 225-237. DOI: 10.1111/1467-8527.00199

Boreham, N. (2004) Orienting the work‐based curriculum towards work process knowledge: a rationale and a German case study. In: Studies in Continuing Education, 26, 2, 209-227, DOI: 10.1080/158037042000225227

Wittrock, M.C. (1974). “Learning as a Generative Process.” In: Educational Psychologist 11, 2, 87–95.

Schön, D. (1987). Educating the Reflective Practitioner. San Francisco: Jossey-Bass.

Pakistan bureau of statistics (2017). Population by 5 year age groups: Pakistan. Online: http://www.pbs.gov.pk/content/population-5-year-age-group-pakistan (retrieved 25.6.2018).

Ali, S & Hafeez, E. (2017). The Pakistani youth buldge: A ticking time bomb. Online: https://www.dawn.com/news/1341111 (retrieved 28.6.2018).

Citation

Pirzada, Gouhar (2018). Application of work process based curriculum development at STEP Institute of Art, Design & Management, Pakistan. In: TVET@Asia, issue 11, 1-13. https://www.tvet-online.asia/issue11/pirzada_tvet11.pdf (retrieved 15.07.2018)