Abstract

“Skills mismatch” and “skills shortage” are very popular concerns in reports on Vietnamese TVET. As a result, many Vietnamese companies struggle to re-train their newcomers after recruitment. Some of them have to accept even unskilled workers who then undergo a “functional training”, for example, welder training and machine assembler, to adapt to the demands of work. Thus, training-at-work has been implemented in most of the Vietnamese companies. However, this process is similar to what has been practised in craftsmanship for years: a repeating process of “watching – imitating – trying – failing – experiencing and working”. There was no place for didactics and educational principles. These companies have difficulty in defining skills, developing a training roadmap and conducting scholarly training. Moreover, TVET in Vietnam is facing supply-side problems (in terms of workers) because TVET institutions merely provide training based on their perceptions instead of paying sufficient attention to employer’s skills demands (JICA 2014). Consequently, there is a gap between the providers (TVET institutions) and the consumers (companies). Therefore, Work-Process Based Curriculum for TVET in Vietnam is now a relevant and suitable solution for supporting training-at-work and to minimize this gap. As a result, the problem of skills mismatch and skills shortage could be solved. However, risk of “functional training” could appear when employers train their workers “just enough” to handle their work tasks, organized according to Taylor’s theory. The tendency of training “functional skills”, in order to adapt to the short term demand, prevents workers from quitting their jobs after training. Moreover, the development of work process based curricula must be done scientifically and based on the results of research on professional qualifications and competencies, which presently lack in the Vietnamese TVET system. The identification of skills needed is not a simple analysis – synthesis process, because the nature of work nowadays is more complex than what it used to be and tends to be an interactive work (work that requires exchange, involves experience, and context), considered as the engine of knowledge economies (USAID 2013). This paper will contribute to the actual state of the Vietnamese TVET, concerning the development of curricula in Vietnam, in particular research on the identification of professional competence through analysing the case study of CNC (Computerized Numerical Control) -operators. It also aims to provide suggestions on the scientific-based job analytical processes that can be applied to define skills needed and cooperation in curriculum development between TVET institutions and the industry sector.

Keywords: work-based curricula, competency, professional profile, National Vocational Qualification Frameworks (NVQs), domain knowledge, declarative, procedural, qualitative research.

1. Introduction

Skills mismatch and skills shortage are the most popular concerns, which were highlighted in the reports on Vietnamese human resources and training (Bodewig et al., 2013). As a result, Vietnamese human resources quality was evaluated and ranked in the lower half in Southeast Asian countries. According to the Research on Cooperation in the Field of Skill Development, Education and Economic Development, “the shortage of engineers, technicians and middle managers is more evident in Vietnam than other advanced ASEAN countries such as Malaysia, Thailand, Indonesia and the Philippines (Mori, Nguyen, & Pham, 2009).” TVET in Vietnam, therefore, is under pressure to “improve and upgrade the skills of its workforce”. This issue is urgent as “one of the key tasks of Vietnam is to meet the rapidly changing labor market needs” (EuroCham 2012, 31), a recommendation of European Chamber of Commerce (EuroCham) in their Whitebook, published in 2014.

1.1 Overview of labour market and skilled worker demand

In the past few decades, Vietnam has become an attractive destination for foreign companies investing in simple and low-technical work in light industry such as textiles, garments and electronic devices assembly. Local companies, meanwhile, only play a role as production companies, which received contracts from foreign clients. Vietnam then moved from the stage of purely Foreign Direct Investment (FDI) absorption to the stage of technological absorption (Ohno 2010), which started in the beginning of the 21st century when some of the inter-continental companies such as Intel and Samsung decided to build their plants in Vietnam. Furthermore, domestic companies, after a long time of being production partners, are willing to invest intensively and pay attention to the design and manufacturing of their own products. The demand for skilled technical workers in Vietnam has been flourishing. However, in order to be a developed country in the near future, moving from the stage of technological absorption and the stage of creativity toward industrialization, Vietnam is experiencing a dramatic change in skill requirements (ibid.). This phenomenon is also known as “all boats float with a rising tide”, urging all companies in Vietnam to carry out their own training courses to enhance the qualifications of their workers. Transition from the Taylorism organized work to a more autonomous work requires a huge number of skilled and trained workers, who can successfully cope with complex and flexible work tasks, which is still lacking at present. It creates further problems for Vietnam when education and training systems are not sufficiently responsive to the needs of skilled labour. As pointed out by Adam Smith in The Wealth of Nations “a man educated at the expense of much labour and time to any of those employments which require extraordinary dexterity and skill, may be compared to one of those expensive machines” (Smith 2007, 84), which is similar to “monozukuri” (Mori et al., 2009), the Japanese definition of a skilled technical worker, “whose work performance is expected to be above the usual common labour” (Smith 2007, 84).

Additionally, many companies in Vietnam have productivity and efficiency problems from recruiting unskilled workers or low-skilled workers, resulting in less efficiency of capital investment and reduced competitiveness. According to “Skill Development for Vietnam’s Industrialization”, Mori indicated that Vietnam “needs human resources who can initiate and manage the improvement of production operations, rather than those who can perform only standard tasks”. Therefore, many companies (domestic and FDI – Foreign Direct Investment) try to deal with this shortage by doing in-company training in the following forms: adaptive trainings, on-the-job training (OJT), and apprenticeships. Although industries are engaged in developing their own workforce, however, the states and schools continue to face an enormous challenge in preparing trainees for work.

Currently, a tendency towards training at work in Vietnam is very remarkable. It is considered as a possibility to enhance the quality of Vietnamese TVET. Nevertheless, it is challenging when comprehensive information on specific skills needed were not scientifically compiled due to the difficulty of establishing collaboration between institutions and firms. This is evident in the policy paper of the Japan International Cooperation Agency (JICA) about Vietnamese TVET: “in Vietnam, many TVET institutions do not properly understand the skills that industry requires” (JICA 2014, 10), “lack of detailed information on specific skills needed at the occupational level” and “the dynamic changes in skills demands make it difficult for TVET institutions to grasp the skills demands of industry” (ibid.). Therefore, “Training programs developed without sufficient information about industry skills requirements cause employees or job applicants to have insufficient proficiency which leads to skills gaps and shortages” (ibid.).

1.2 Issues and challenges in TVET

Training-at-work is the corollary reaction of the industry to address the skills gaps and shortages. There are many of those responses conducted by both FDI and domestic companies such as initial training (Vo 2018) where the companies recruit unskilled workers and train them functionally at workplaces. This initial training is widely organized in the field of textile, construction and even mechanical engineering such as welders and machining assembler. The work is divided into simple tasks and involves assembling and manufacturing procedures with repetitive processes. Another common form of training in Vietnam is “adaptation training” (ibid.) when firms train their trainees or graduates coming from vocational schools or colleges that are not ready to work and have inadequate skills to start working immediately after recruitment. In this training form, the trainees will be trained under guidance of an experienced person who acts as a coach or mentor until the trainee can independently handle complex tasks such as operating CNC or conventional machine, assembly electrical boards of fly-cam, etc. It requires the firms to invest sufficient time and resources for enhancing their workforces, since it is particularly beneficial for both employers and employees. Companies that use this form of training often desire to upgrade to advanced training (ibid.), which could be done along the professional life of the workers. For example, in the case of upgrading manufacturing system (from a 3-axis-CNC-system to a 4 or 5-axis-CNC-system), most of the companies have to ask their client whose offer this system to train their workers how to operate the new machine (ibid.).

This is a very significant commitment of the industries in Vietnamese TVET. It can develop further when the industries try to develop a model for within-company training such as teaching firm on the account of solving the skills mismatch. Teaching firm is defined by the Education Development Center -USA, as “an environment in which teaching and learning are institutionally and culturally embedded in the organization and are perceived to be beneficial to both the firm and the individual” (Education Development Center 1998). This is not a monopoly phenomenon in TVET in Vietnam now compared to circumstance of the 80s to 90s of the last century. It has become increasingly popular in recent years for international corporations such as Bosch, Intel and Samsung to set up their plants in Vietnam. This is similar to the model of quality apprenticeship, conducted in the USA (Aring 2014), which was introduced by German companies like Siemens and Volkswagen when they built their factories there.

In the case of Vietnam, Bosch has collaborated with a Vietnamese TVET institute, the Lilama2, to provide training courses. The TVET institute takes responsibility for teaching theory while the company trains their trainees in terms of technical skills within the training center or on-site. Previously, Lilama2 also conducted the same model for welder training, here trainees were trained under the supervision of the on-site skilled workers and learned theories in the classroom. This may be similar to the “dual model”, an extremely successful and accepted model around the world, used in Germany and some German-speaking countries such as Austria and Switzerland.

Some Vietnamese companies (such as PetroVietnam Technical Services Corporation – PTSC and Duy-Tan-Plastics-Corp…) want to use this model. However, it can lead to an immediate harm which is identified as “functional training” (Gonon 2011), where the trainees may be trained functional skills just enough to handle their tasks in specific working context which are divided small enough to be implemented within 2- 3 months. Nevertheless, it depends on the level of work division in the company. This indicates that the company pays greater attention and emphasis on practical subjects and hands-on training rather than on theoretical instruction. Furthermore, due to the lack of the National Vocational Qualification Frameworks (NVQs) (General Department of Vocational Training 2012) as a guideline, this form of training occasionally becomes initial training to prevent workers from leaving their jobs after training. Additionally, this may be caused by the limited capability of training staff whose gained their experiences only from mentoring the hands-on training of certain specific jobs, and also an overall lack of involvement of curricula as a roadmap for training processes.

Moreover, Vietnamese companies are struggling with the organization of curricula development for training courses. They can easily determine skills needed since they have enough technical facilities and also human resources (e.g. skilled workers) for the on-site training as well as a lot of experiences in on-the-job training (from previous training activities: adaptation or advanced training). However, they have difficulty in sketching out a roadmap from identifying the skills needed to develop curricula and implement in teaching firms. Finally, informal learning, especially OJT, existed as an undeniable truth in Vietnamese TVET for a long time and was separated from the rest of TVET system managed by the state.

Therefore, the need of an outline from the definition of the skills needed and profiles of professions (German – Berufsbild) as a reference for within company training, for acknowledgement of informal training and for certifying and accreditation of TVET training forms, is urgently to be realized. Moreover, research on skills needed and profiles of professions as a milestone in curriculum development to meet the demands from companies and workers and as a realistic solution for skills mismatch in TVET in Vietnam, must be intensively and scholarly implemented. Thus, the linkage between TVET system in Vietnam and the whole industry can be created.

DACUM (Developing a Curriculum) was introduced as a tool for job analysis within a project with Switzerland, held in Vietnam to train DACUM-Facilitators in 1999, who then were expected to be key persons for job analysis processes. The project supported vocational-technical educators to describe jobs using a DACUM-matrix, which would later serve as a foundation for developing a curriculum for specific job training courses. DACUM involves developing a list of job-specific skills needed for the specific work process in form of a matrix, which is divided into steps, tasks and duties according to an inductive way to find out the needs of a job position or a whole job concerning knowledge, skills and behavior of workers that are required in the real world of work. Moreover, the process also identified “enablers”, which workers may need in the work process such as tools, equipment, etc.

The philosophies of DACUM are that “expert workers are better than anyone else to describe their occupations” (Norton 1997, 54) and “successful task performance is directly related to the knowledge, skills, tools, and attitudes” (ibid.). In actual practice, qualification requirements for specific positions of certain jobs at specific companies cannot be considered as a representative of the job in the real world of work. These requirements need to be integrated for the whole industry (Bank 2015). The process of DACUM depends totally on the capability of the facilitators and the quality of invited expert workers. However, results from this process only reflect their points of view about certain jobs at a specific company. Even in the establishment of standards on occupational skills by the Ministry of Labour – Invalids and Social Affairs (MOLISA), Vietnam has set the policy that “members from enterprises in the board of directors develop standards on occupational skills make up of approximately 50% and suggestions from at least 30 experts play significant role in all steps involved for developing the national standards on occupational skills” (General Department of Vocational Training 2012).

However, during the development of a set of occupational skills for the CNC-machine operator, resulted from a pilot project under support of the GIZ (Deutsche Gesellschaft für Internationale Zusammenarbeit), conducted in 2011, were only 4 out of 9 experts from companies participated and the rest came from TVET institutes. It is the reason why this skill set, later on, had no real impact as a guideline for TVET-training. Consequently, there was no proof of qualitative research on skills needed during the process of occupational analysis.

1.3 Problems in the implementation of TVET

As stated in the assessment of JICA’s policy paper about TVET in Vietnam “The lack of detailed information on specific skills needed at the occupation level and the dynamic changes in skills demands make it hard for TVET institutions to grasp the demands of the industry”. Therefore, curriculum development of TVET in Vietnam is not based on relevant information about skills needed from industry. As a result, TVET institutions provide training courses mostly based on their perceptions and are not paying sufficient attention to employers’ skills demand. This is due to lack of connection between industry and TVET institutions: no proof of qualitative research on skills needed and also an inactive role of vocational schools in state-controlled system, hence, TVET institutions as a provider of labor resources cannot consider how fast the world of work changes and which new skills are needed.

Under the circumstance where there is no national qualification framework consistent with the national vocational qualification framework (NVQs) (General Department of Vocational Training 2012), TVET in Vietnam has sought to develop the national framework of occupational skills, for example, for the job of CNC machining (ibid.) under support and consulting of German experts. They intended to create a tool to:

− Support employees to orient their efforts to improve professional qualifications (knowledge and skills) through self-studying or gathering experience in order to have a chance for promotion in their occupations;

− Support firms to use it as a reference for recruiting employees, managing jobs or working positions and paying proper salaries to their employees;

− Support TVET institutions to use it as foundation for developing a vocational training program in order to approach the national standards on occupational skills;

− Support competent authorities or centers to have a fundamental reference for evaluating professional skills and accreditation of national occupational skills certificates for the employees.

However, the “passive and dim” participation from the industry (ibid.) and the process of establishing the national framework of occupational skills only involved TVET institutions and some enterprises which were not enough to represent the whole industry. Meanwhile, the world of work is richly diverse. Consequently, the established national framework of occupational skills had almost no impact on industry and could not be a qualification-driven factor for solving skills mismatch as expected. This results in the fact that the qualification of the national standards on occupational skills is limited in terms of relevance for the labor market.

In addition, as mentioned above, the world of work is very diverse. For instance, in CNC-domain, various software of Computer-Aided Design/Computer-Aided Manufacturing (CAD/CAM) such as Pro-E, AutoCAD, and Mastercam are exerted to design machine parts, various operation systems (Heidenhain, Okuma, Sinumerik, Fanuc…) are also applied to control CNC-machines or processing centers. Thus, a training course for the CNC-machining job does not match with what is happening in the real work. According to laws of technical and vocational education (TVE) in technical and vocational schools, TVET programs that has practical training may claim a minimum of 40 percent (may increase to 50-60 percent) of the institutional time. However, the availability of facilities, equipment and staff with relevant expertise are improper in order to achieve learning outcomes of the training course.

Contrary to the weakness of the implementation of practical training, however, the interviews with the workers conducted in 2017 revealed that TVET institutions have done very well in conveying jobs’ professional theories. All of the interviewees confirmed that theories they had learnt are very useful in their present careers. Nevertheless, they had difficulty in adjusting their CNC machine independently after being recruited due to inadequate training at vocational schools. This is confirmed by the company’s managers and it is the reason why companies often train their workers after hiring. Finally, TVET institutions in Vietnam, due to the capacity of equipment and professional staff, currently provide only training courses for mechanics (mechanical engineering) that emphasize on conventional machines such as lathe, milling machine, etc.

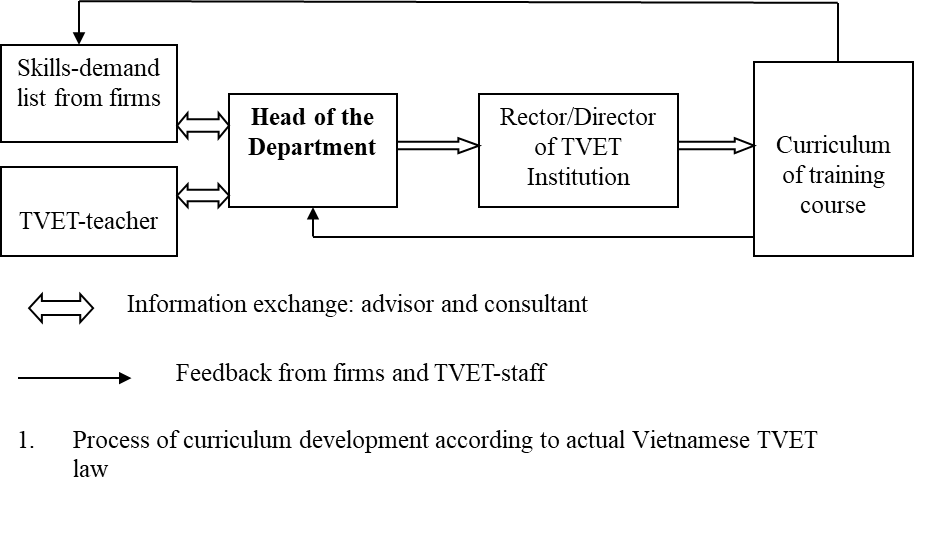

Moreover, Vietnamese TVET law, although, encourages firms to provide information about expected skills needed of their human resource and promote the active role of rector/director of TVET institution, who is responsible for issuing a new curriculum for a training course. However, the information of skills needed from those firms is simply a list of demands, what they expect from graduates whom they could later recruit. It is rather a raw data, not analyzed and not good enough as a resource for curricula development and this information is sent to TVET institutes separately via e-mail. The firms are aware that their sensitive information about technology, human resource and business plan are not to be unfolded. Therefore, it is difficult for TVET institutes to gather necessary information for the development of a work-based curriculum.

At present, the process of curriculum design can be briefly described in Figure 1, the head of department will enroll as a facilitator in the process to collect skills-demand lists from firms under the consultants of teaching staff in the department in order to sketch out a curriculum. Later, the draft of the curriculum will be sent to firms for feedback before getting issued by the rector or director of the institution. The curriculum will then serve as a guideline for the new training course. Corrections and modification occur every year when they receive feedback from firms that employed graduates who were trained by this course. These suggestions will be sent to the TVET institutions, mostly to the head of the department who is responsible for the quality of the training course. The curriculum can be used for 5 years before being replaced by the new one. The exchange of information between the host of curriculum design (head of the department) and firms is done normally through meetings or indirectly by submitting documents.

1.4 Purpose of the study

The purpose of this study is to develop a work process based curriculum in order to overcome skills mismatch and skills shortage in Vietnamese TVET. The newly developed curriculum is expected to benefit training providers and relevant industry in the country. This is in line with the country’s mission to develop a more competent workforce in the future. In order to achieve this purpose, three objectives have been set as follows;

(a) To find out the current situation of CNC machining work sector in the country

(b) To identify skills needed

(c) To develop a work-process based curriculum guide for CNC machining work.

2. Need of a work-process based curricula development approach

Due to the lack of collaboration with the industry, the development of curriculum has not been based on relevant information on required skills from the industry. Therefore, training provided by TVET institution is merely based on their perception and not on employers’ skills demand. What actually happens is that the companies simply provide a list of demands which they expect from graduates whom they plan to recruit. Consequently, the established national framework of occupational skills had almost no impact on the industry and could not be a qualification-driven factor for solving skills mismatch as expected. Therefore, it is the right time for the curriculum developers to adopt the work-process based curricula development as an approach to alleviate those problems.

2.1 CNC employment sector in Vietnam

In the CNC-domain, a job is usually divided into 3 positions namely an operator, a programmer and a designer, where job requirements for each position are diverse. The operator is responsible for operating the CNC-machine or the processing center for the completion of the parts, sketched by the designer under construction of a programmer through the form of machine-generated, which is written and repaired by a programmer. Firms usually look for trainees from vocational schools to recruit for the position of the CNC-operator. At the same time, they will employ graduates from colleges or even universities for the position of the programmer and designer. Although the work of those two positions is mainly done by using software and computers but, according to the interviewees, having the experience as the CNC-operator is extremely important and plays a vital role to support programming and designing because it provides the “fantasy” about the reality of machining process.

2.2 Case study and work process analysis

In order to develop the “know-how” about the job, analysis is required. In this case study, the qualitative interview method is used to identify the tasks, required knowledge and attitudes that the job demands. By asking a set of questions concerning required tasks that arise during the daily work shift, such as:

− Which tasks do you have to do every day from the beginning to the end of the shift?

− What kind of knowledge do you need to master your duty in reference to these tasks?

Moreover, with the aim to improve learning outcomes of training courses in TVET institutions, the interview also intended to ask about problems and difficulties that were encountered at work. Asking for their reactions when they come across certain challenges at work was meant to record the attitudes and soft skills requirement, which is needed and very relevant for the job. Information about the interviewees’ graduation is also important to determine what the training course has done well and what needs to be added to improve the curriculum. Consequently, interviewees, one of the relevant factors in determining skills needed, must be selected carefully.

Based on this research, it is recognized that the domain knowledge is very important as a core-knowledge and plays an important role in mastering the job. The core-knowledge consists of declarative and procedural knowledge. Declarative knowledge contributes to the workers’ thinking process and is very helpful in adapting to changing work conditions and achievement of new knowledge. Without this knowledge, workers may experience problems when their tasks change. This usually happens in companies that recruit unskilled workers and train them functionally at the workplace. After training, the workers do what they learned. Once they can handle the task properly, they are more likely to reduce the work process to get their job done faster, regardless of what they have done.

Declarative knowledge is based on the development of a working life. According to the interviews results, TVET institution had done relatively well in teaching because workers have confirmed that knowledge, such as mathematics, technical communications, machining elements, machining processing, technology of technical measurement, materials, etc., learned at TVET schools, are very useful in supporting them to fulfil their tasks, solve the challenging problems and make adaption to new tasks easier. Meanwhile, interviewees also agreed that they had difficulty in handling CNC-machine and in applying their knowledge, although, according to the TVET laws, practical training may claim a minimum of 40 percent of institutional time, and even increase up to 50-60 percent. The procedural knowledge and practical skills are the weakness of the Vietnamese TVET since the facilitators and trainers are not able to guarantee the time required for the trainees to spend on machine to master the skills for operating the CNC machine. Besides, trainers at TVET-institutions do not have enough practical experience. This leads to lack of core skills, such as the independent use of the CNC machines and solve problems that may occur during the time of operation. Through the implementation of job analysis, some remarks can be identified, such as:

− The interview should focus on tasks that workers have to complete during a work shift, which also involves working with objects such as tools, machines, and equipment. Then, requirement of skills needed can be identified, and the level of completion of a task is determined. Consequently, level of complexity depends on the position of the job, here workers just get involved with computers and software and do not work with specific objects such as the CNC-designer. It requires that the interviewer should have experience in work analysis and must be fully prepared, showing a friendly attitude and being well informed about what he/she wants to achieve by conducting the interview in terms of tasks, domain knowledge, core-competencies, skills etc. For example, in the case of analyzing the position of the CNC-designer, the interviewer has to understand what designers do in order to describe the exact skills needed of the positions.

− It is difficult to determine attitudes and soft skills needed for the job. Years of experience are very useful to identify them. Workers with less experience will express the views of newcomers. Meanwhile, the experienced interviewees would provide the whole information about a job. Therefore, the size of the samples must be large enough to cover many ranges of experience.

− Unpredictable skills needed of a job could be defined by a manager who knows well about the developing plan of the institution in future and also about the development tendency of the job such as the CNC-operator should have the ability to write a CNC-program (programmable ability).

− Expectations of the managers are always higher than the workers’ actual ability but it is a very important and useful resource for designing work-based curricula.

− Dilemma in distinguishing the difference between jobs and positions is a barrier in determining what should be taught in a training course because the duration of the training course is limited and TVET institutions cannot train the trainees to meet the demands of every single firms.

2.3 Curriculum development work

Through focus groups and workshops, experts and skilled workers from the industry have met and come up with a guideline which stipulates that skills needed should include the following elements:

− Expected tasks which workers have to fulfil with requirement of completion (expectation of firms about achievement of tasks), e.g. the CNC-operator has to handle CNC milling machine to perform work from the beginning to the semi-finished product in accordance with the construction of a technical drawing.

− Requirements about the level of the task completion, e.g. the CNC-operator must understand and leave surplus stock properly according to the given technical documents.

− Requirement of qualifications that includes knowledge, skills and attitude, which a CNC-operator should possess e.g.:

– Knowledge of cutting tools, operating principal of CNC-machines, technical drawings, jig, processing documents, CAD-software…

– Skills: setting up parameter for work parts in order to process it until finish, handle with software Cimco Edit to operate CNC-machine, …

– Attitude: careful, concentrated, disciplinary, positive, responsible…

− Objects or equipment that the CNC-operators deal with e.g. software, machine, equipment, cutting tools, and personals.

With this specific information, firms can easily find benchmarks and find out which skills needed are to be trained to their workers so that a training plan can be developed to address this mismatch.

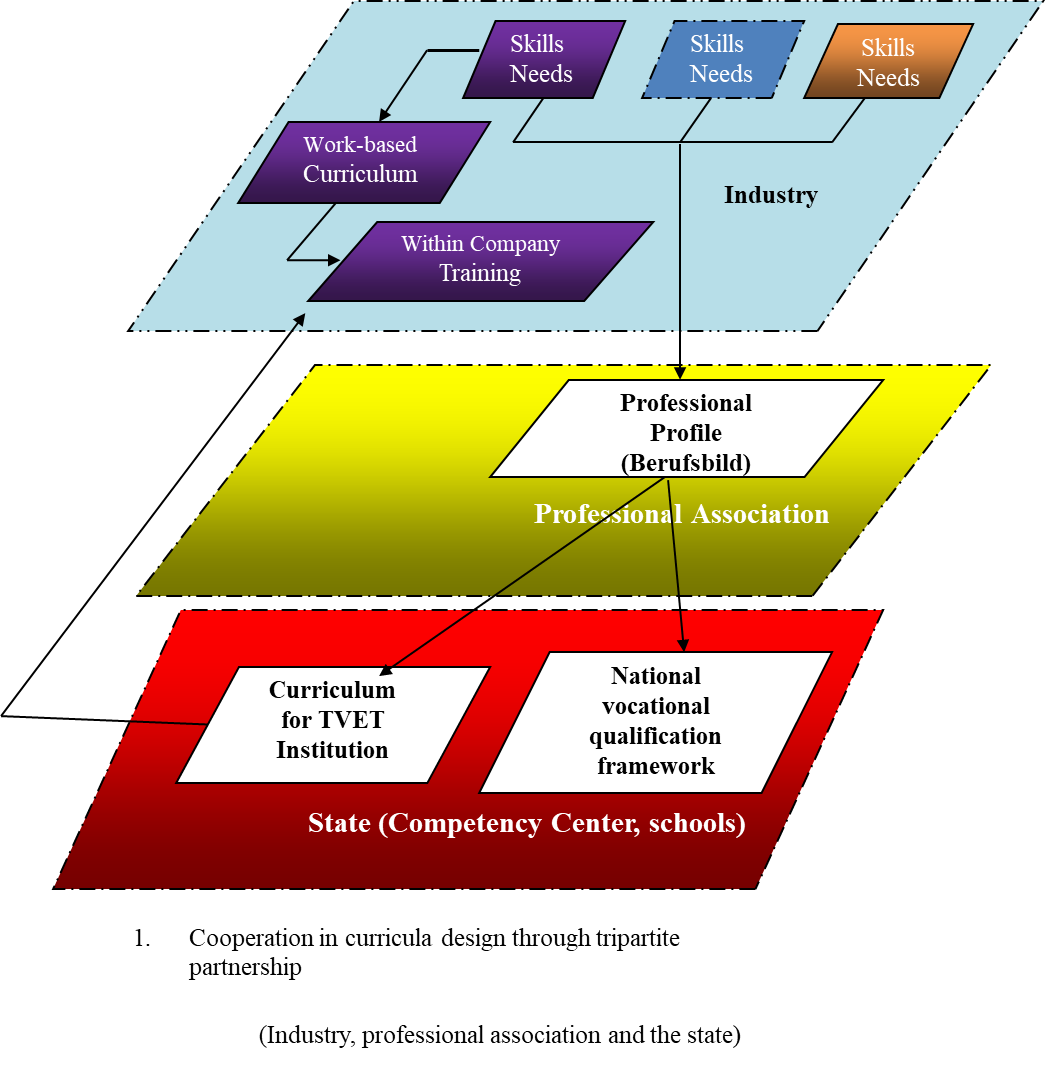

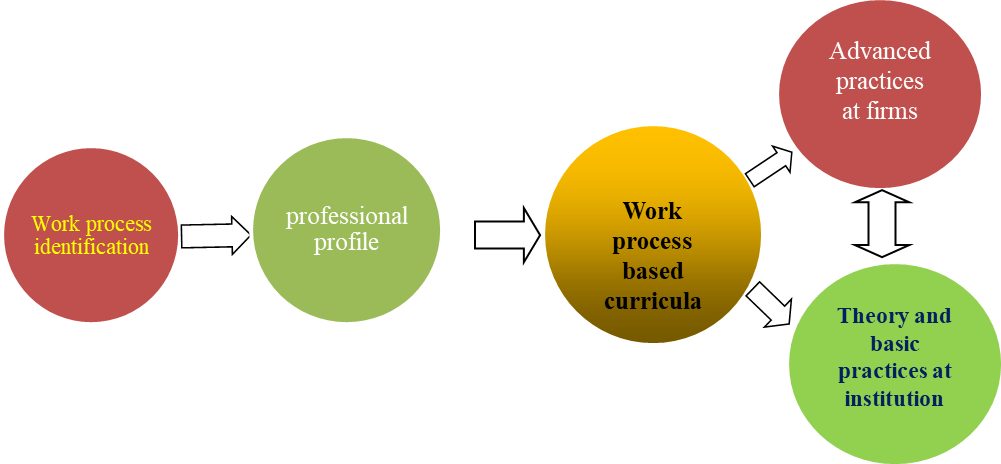

As described above, skills needed for CNC-operators can be a relevant information resource to develop curriculum for within company training courses, primarily used at certain firms, in order to fix skills mismatch. In addition, skills needs set can be send to TVET-institutions as a suggestion from firms about expected qualification of graduates. It makes the process of developing curricula easier and more effective (figure1), not only for adapting training at firms but also for formal training courses at TVET-institutions. Besides, it can become a professional profile after the process of quantitative research, which can be done in form of questionnaires send to other companies of the same domain. Therefore, it will be a representative for the work of CNC machines as the CNC-operator, a professional profile, which is considered as a reference of curricula design for vocational training course for “CNC-operator”, and as a reference for building up the National Vocational Qualification Frameworks (NVQs) for the “CNC-operator” (Figure 2). As a consequence, curriculum based on the professional profile, can be accepted and used in coordination in TVET between vocational schools and the industry because it plays a role of an agreement from both stakeholders through quantitative research. Professional profile, counted as a central point of TVET, in order to enhance cooperation between the industry and vocational institutions, makes TVET process in Vietnam more transparent, assure quality of trainees, and also acknowledge informal form of training at firms.

3. Findings

Developing a work-based curriculum in a certain firm is only the first step in developing a quality training program that will be formally implemented in TVET-institutions. This process depends on the complexity of tasks and division of work that is different in each company.

A professional profile is just representative and reliable when it is investigated further by another quantitative research under the form of questionnaires, sent to other companies in the same domain, in order to filter core-skills or core-competencies, which are representative and typical for the job. Therefore, professional association plays a very important role in defining professional profiles (Figure 2), and the competency centre (may be organized by TVET-institution, professional association or firms) is responsible for the quality assurance of TVET in Vietnam. The three organisations are currently expected to be more active in TVET in Vietnam.

Work-based curriculum is at present developed for adaptation training at certain companies. It needs to be recognized as a formal training course, even if it did not take place at a TVET institution through the effort of connecting firms from the same technical domain to meet and work together in order to establish the professional profile of the job, that they demand.

There is no universal system that is ideal for all situations. Therefore, Work-based curriculum should be considered as a bridge connecting between TVET-institutions and firms. It acts as an agreement to assign work in enrolment and division of teaching tasks in training processes where the TVET-institution will be the host to provide theories and basic practices while advanced practices (such as quality apprenticeship) will take place at certain firms where the curriculum will be designed. TVET personnel is expected to be more active in contacts with firms in order to analyse jobs and skills needs identification as well as to support them. This is an effective way to approach the demand of the industry. Consequently, in the process of conducting qualitative and quantitative interviews not only firms but also the teaching staff from TVET-institutions should participate (figure 3). Then, both sides (firms and TVET institutions) could unify which parts of the curriculum they will teach. For example, TVET institutions teach trainees theories and basic practical training will happen at school then trainees will be sent to firms to perform advanced practices. The division of duty in training could help stakeholders to understand clearly about their part and make training process more transparent and effective. This will create corporation among TVET stakeholders and eventually bridge the gap.

|

Work-based curriculum is a very practical solution to help TVET in Vietnam to move from the state of supply-driven skills development to demand-driven skills development. It could be a promising solution to approach a mechanism for skill development by social partnership in which skills needs set is issued annually by the professional association and professional competency be evaluated by competency centers under the supervision of the government.

4. Conclusion

Curriculum as a roadmap for imparting knowledge and basic skills to learners (trainees) in order to prepare for integration into professional life and supporting their development in the future. In the context of industry 4.0, workers are required to be able to adapt to rapid changes in technology and meet higher demands and more complex functions at work. The nature of work is now not a list of visible tasks anymore but includes also invisible tasks such as quality awareness, perception of time management, etc. Therefore, DACUM may not be suitable tool anymore. Curriculum development, especially work-based curriculum, needs more research not only qualitative but also quantitative research on professional qualification and profile, relevant information resources to design training courses that meet the demand of skills needs from the industry and thus bridge the skills gap. Thereby preventing the risk of functional training, which would have a negative effect on professional career promotion and competence development of the workers. Consequently, work-based curriculum is as a remarkable proof of cooperation between TVET institutions and industry in the circumstances where there is a lack of the practical connection between those stakeholders. Based on qualitative research in Duy-Tan-company, the author recognized the need to develop guidelines for qualitative interviews in order to provide educators in TVET-institutions and personnel in firms with a tool that is more efficient than DACUM, in terms of work analysis and defining skills needed. Moreover, a model of cooperation in curriculum development will be introduced to enhance connection between TVET-institutions and industry in Vietnam.

References

Aring, M. (2014). Innovations in quality apprenticeships for high-skilled manufacturing jobs in the United States at BMW, Siemens, Volkswagen. Geneva: PRODOC International Labour Office.

Bank, V. (2015). Curriculare Ausgestaltung beruflicher Bidlung: Koordination staatlicher, parastaatlicher und privater Akteurer durch Pläne. In: Governance und Finanzierung kooperativer Berufsbildung: die Rolle von privaten Akteuren und Verbänden stärken, Bonn: GIZ.

Becker, M., Spöttl, G. (2006): Berufswissenschaftliche Forschung und deren empirische Relevanz für die Curriculumentwicklung. In Berufs- und Wirtschaftspädagogik Online: http://www.bwpat.de/ausgabe11/becker_spoettl_bwpat11.pdf (retrieved11. 01. 2018).

Bodewig, C., Magnusson, B. R., Macdonal, K., Newhouse, D., & Rutkowski, J. (2013). Skilling up Vietnam: Preparing the Workforce for a Modern Market Economy. Retrieved from the World Bank Website: http://dx.doi.org/10.1596/978-1-4648-0231-7. (retrieved 31.01.2018).

Ebeling U., Gronwald D., Stuber F. Revison und Entwicklung von Curricula in der gewerblichen Ausbildung. Online:https://www.fhmuenster.de/ibl/downloads/projekte/informationsportal/ebeling__gronwald__stuber_-_revision_und_entwicklung_von_curricula.pdf (retrieved 24.04.2018).

Education Development Center, Inc. (1998). The Teaching Firm: Where Productive Work and Learning Converge. Report on Research Finding and Implications. Newton, MA: ERIC. Online: https://files.eric.ed.gov/fulltext/ED461754.pdf (retrieved 26.06.2018).

General Department of Vocational Training (2012). TVET Quality Breakthrough. Vietnamese TVET Background Paper. Hanoi: Vietnamese Ministry of Labor – Invalids and Social Affairs (MoLISA).

Gonon, P. (2011). Ist das duale Berufsbildungssystem ein Zukunftsmodell? In: Künzli, R; Maag Merki, K. Zukunft Bildung Schweiz: Akten der Fachtagung vom 21. April 2010. Bern: Akademien der Wissenschaften Schweiz, 109-118. Online: https://doi.org/10.5167/uzh-50108 (retrieved 24.04.2018).

JICA (2014). Promoting tripartite partnerships to tackle skills mismatch: Innovative skills development strategies to accelerate Vietnam’s industrialization. Online: https://www.jica.go.jp/vietnam/english/office/others/c8h0vm00008ze15n-att/policy_paper.pdf (retrieved 26.06.2018).

Jongebloed H. C. (1998). Komplementatität als Verhältnis: Lernen in dualer Struktur. In: Jongebloed H. C. (Hrsg.) Wirtschaftspädagogik als Wissenschaft und Praxis – oder: Auf dem Wege zur Komplementarität als Prinzip (Moderne der Tradition, Bd. 1), bajOsch-Hein, Verlag für Berufs- und Wirtschaftspädagogik, Kiel, 259-286.

Mori, J., Nguyen, T. X. Y., & Pham, T. H. (2009). Skill Development for Vietnam’s Industrialization: Promotion of Technology Transfer by Partnership between TVET Institutions and FDI Enterprises. In: Mori, Nguyen, & Ohno (2008): Research on Cooperation in the Field of Skill Development, Education and Economic Development. Vietnam.

Norton, R. E. (1997). DACUM Handbook – Leadership Training. Ohio: Center on Education and Training for Employment. Online: https://files.eric.ed.gov/fulltext/ED401483.pdf (retrieved 09.05.2018).

Norton, R. E. DACUM Handbook (Kommentar), Online: http://www.biat.uni-flensburg.de/current/Pdf/Material/Ma-A/Ma-A-IV.pdf (retrieved 09.05.2018).

Ohno, K. (2010). Avoiding the Middle Income Trap: Renovating Industrial Policy Formulation in Vietnam. Vietnam Development Forum (VDF), Hanoi National Graduate Institute for Policy Studies (GRIPS). Tokyo.

Smith, A. (2007). An Inquiry into the Nature and Causes of the Wealth of Nations, MetaLibri Digital Library. Online: https://www.ibiblio.org/ml/libri/s/SmithA_WealthNations_p.pdf (retrieved 09.05.2018).

Smith, A., Blumenstein, G., Boehm, U., Ebeling, U., Gronwald, D., Schade, E. (1998). CURRENT – Orientierungshilfe zur Curriculum Revision und Entwicklung. Online: http://www.biat.uni-flensburg.de/current/Pdf/Orientat/Text/O-Text.pdf (retrieved 11. 01.2018).

Vo, X.T. (2018). Informal Learning in Vietnam: Status quo, Circumstances of existence and the demand to be acknowledged. In: TVET@Asia, issue 10, 1- 18. Online: https://www.tvet-online.asia/issue10/vo_tvet10.pdf (retrieved 31.01.2018).

Citation

Vo, X. T. (2018). Work Process Based Curricula for TVET in Vietnam – inevitable tendency and how to prevent a functional curriculum. In: TVET@Asia, issue 11, 1-16. Online: https://www.tvet-online.asia/issue11/vo_tvet11.pdf (retrieved 10.07.2018).