Abstract

The article discusses the uptake of formal and non-formal training programs in Vietnam’s manufacturing sector and explores company and production managers’ perception of the programs. The study is based on a survey of 162 companies in the electronics, food and beverage, and garment industries, and in-depth interviews with a sub-selection of these companies. Findings indicate a substantial reliance on and appreciation for in-employment training, evident through high uptake rates. Non-formal training is recognized for its perceived efficacy in addressing current industry-specific skill gaps and also ensuring future competitiveness in a sector that is constantly evolving. Conversely, formal TVET programs, while also viewed positively, garner less enthusiasm, particularly for lower-level positions. The underdevelopment of the formal TVET system necessitates a shift towards non-formal and informal training, often provided by technology-transferring entities, creating a competitive advantage over traditional TVET providers. Despite this, the study argues for the complementary roles of formal and non-formal training, emphasizing the need for the formal TVET system to incorporate elements that enhance its labor-market relevance.

Keywords: Formal training, non-formal training, manufacturing, Vietnam

1 Introduction

The transition of Vietnam from an agricultural to an industrial and service-based economy, coupled with the government’s open-door policy and the influx of foreign direct investment (FDI), has created a pressing need for a skilled workforce. With FDI companies establishing a strong presence across the country, particularly in the electronics and footwear industries, the vocational education system faces immense pressure to train individuals who can effectively meet the high requirements of companies as well as the societal demands to provide all young people with decent work.

In this context, formal, non-formal, and informal training all play a crucial role in developing a skilled workforce. This article aims to explore the perceptions of companies in the manufacturing industry regarding formal and non-formal training programs and focuses on two research questions: 1. To what extent are formal and non-formal training used in Vietnam? 2. What are the contributions of formal and non-formal training programs to addressing skills shortages, fostering transformation, and promoting growth in Vietnam?

Understanding these perceptions seems crucial for addressing the skills gap and ensuring the effective alignment between training and industry needs. However, despite the apparent needs, there is still little research into the wider skills formation system in Vietnam, and its longer-term effect on growth and transformation. By examining the perspectives of companies, this research seeks to contribute to the research body and policy discussion on strategies that enhance the quality and relevance of training programs, ultimately bolstering Vietnam’s economic growth and the performance of businesses operating in the country.

2 Literature reviews

The landscape of education and training is often characterized by three distinct forms of learning: formal, non-formal, and informal. This classification, stemming at least as far back as the Faure Report commissioned by UNESCO in 1972, continues to maintain its relevance in contemporary educational discussions, as evident in recent scholarly publications and policy documents (e.g., OECD 2023). However, it is important to acknowledge that these categories are not rigid and that there are overlaps between them.

Formal learning, distinguished by its structured nature, takes place within established educational institutions, and leads to the granting of recognized qualifications. These qualifications include certificates, diplomas, and degrees. This type of learning spans a variety of durations and formats, ranging from long-term academic programs to short-term training sessions, with successful completion often conferring specific legal privileges. These privileges can manifest in several ways, such as access to specific professions, increased earning potential, and distinct legal and professional advantages. Misko (2008) points out that formal learning remains the primary path to recognized qualifications necessary for job entry, particularly in professions with regulatory requirements.

Conversely, non-formal learning retains a structured form but does not result in formal qualifications. Within the workforce, non-formal training methodologies, including in-house training programs and equivalent initiatives, are prevalent. Richardson (2004) and Mawer & Jackson (2005) provide empirical support for the widespread adoption of such training practices, especially within small-to-medium-sized enterprises. Non-formal programs have emerged as pivotal in imparting skills and knowledge swiftly, addressing immediate organizational requirements not met by formal TVET programs. Empirical studies in different sectors and regions have underscored the significant positive correlations between non-formal TVET programs and outcomes related to job performance, job satisfaction, and the enhancement of personal skills (Kanapathipillai & Azam 2020; Asiyai 2018).

Informal learning, characterized by its less structured format, emerges spontaneously from daily work-related activities, social interactions, hobbies, or leisure pursuits. Despite its absence of formal recognition, it plays a crucial role in lifelong learning, facilitating the acquisition of practical knowledge and skills. Kominarets et al. (2022) affirm its effectiveness but also draw attention to its limitations, advocating for a balanced integration with structured educational practices.

From an employer’s standpoint, the outcomes of learning—such as mastering technical skills, meeting legal requirements, and honing soft skills like problem-solving and communication—take precedence over the format of learning (Misko 2008). The effective implementation and interplay of formal, non-formal, and informal learning are critical in addressing the diverse skills needs of both individuals and organizations. Efficacy is contingent upon various factors, as articulated by MacDonald, Nink and Duggan (2010), who outline key principles for successful TVET programs. Although their focus is predominantly on formal TVET, these principles—relevance, flexibility, learner-centeredness, and quality assurance—are also applicable to the other forms of training.

2.1 Formal and non-formal training programs in Vietnam

Vietnam’s vocational training landscape, including both formal and non-formal programs, falls under the jurisdiction of the Ministry of Labour, Invalids, and Social Affairs (MOLISA) and its subordinate entity, the National Directorate of Vocational Education and Training (NDVET). NDVET’s responsibility spans the issuance of policies, regulations, and guidelines, ensuring standardized practices across training activities. Meanwhile, the Ministry of Education and Training (MOET) oversees higher education institutions.

Presently, Vietnam’s TVET system encompasses 1,905 institutions, segmented into 410 colleges, 437 intermediate schools, and 1,058 vocational education centres. In parallel, the higher education system, led by MOET, comprises 460 universities and colleges, which include 224 universities and 236 colleges. Both these educational frameworks function to supply skilled labor across industries, adhering to the 8-level national qualifications framework.

The key distinction between vocational and higher education in Vietnam lies in the allocation of time. Vocational education predominantly focuses on practical skills, dedicating up to 70 percent of learning time to internships, with the remaining 30 percent focused on theoretical knowledge. This approach aims to prepare students for a variety of roles ranging from frontline production to technician positions. On the contrary, higher education reserves a larger portion, up to 70 percent, for theoretical knowledge acquisition, producing graduates fit for positions such as supervisors and managers. Despite the difference in focus, both systems aim to fulfill industry demands by providing well-rounded human resources, from entry- to high-level positions.

In this educational context, associations and companies are permitted to offer non-formal training courses. However, the qualifications obtained from these courses are not recognized nationwide, unlike those from formal training programs. Only TVET providers and universities, under government oversight, offer formal training programs that yield nationally recognized qualifications.

The TVET system can be classified along a spectrum from a demand-driven or employer-led model, partnership model, to a supply-driven or school-based model (Dang & Nguyen 2023). In Vietnam, the government predominantly adopts a supply-side approach, aiming to meet industry needs by offering free training to cultivate a skilled workforce. Despite these efforts, challenges persist, echoing global observations by scholars like Crouch et al. (1999) about the limitations of state-led skill-development initiatives. As further explored by Booth et al. (1996) and Finegold (1996), these challenges stem from potential misalignments in government officials’ interests, possible gaps in understanding the specific skill needs of businesses, financial strains from state-funded training, and a tendency of policymakers to favor short-term gains over sustained skill development.

Research conducted by organizations such as the Asian Development Bank (ADB), the World Bank (WB), the International Labor Organization (ILO), and UNESCO has underscored a disparity between the outcomes of formal TVET providers and industry requirements. Although formal TVET programs have undeniably driven growth across various sectors in Vietnam, there is a noticeable gap between the competencies of graduates and the expectations of employers.

The ADB 2020 report criticizes the outdatedness of TVET programs, particularly in technology sectors like electronics, stating “TVET graduates do not have industry-relevant occupational skills as well as fundamental soft skills … Prevailing reasons for this relate to the TVET system’s persistent focus on school-based training delivery … and a range of problems including lack of instructors with industry experience, poor standards, and inefficient resource management.” Furthermore, the underdevelopment of facilities, equipment, and technological resources hinders the ability to meet corporate and market demands. “Outdated or insufficient training facilities and poor resource management appear to constrain Viet Nam’s TVET system,” impacting the quality of training and the capacity for practical, hands-on training for all enrolled students (ADB 2020).

3 Methodology

To respond to the research questions, a sequential design, combining both quantitative and qualitative methods, was utilized. The data stems from a company survey, as well as a round of in-depth interviews with management and production leads in a sub-sample of the surveyed companies.

First, 162 managers of companies in three manufacturing industries—garment, electronics and food processing—were invited to participate in a survey, conducted in a face-to-face format. Several factors inform the choice of industries. First, they all align with Vietnam’s industrial development strategy for 2025, extending to 2035. Furthermore, they feature prominently in Vietnam’s export landscape, with all three ranking among the top five export sectors. Additionally, TVET providers offer a range of training programs, encompassing both formal and non-formal training.

Companies were selected based on the following criteria: (1) minimum of 50 employees, targeting medium and large companies; (2) active in the Electronics, Food & Beverage, and Garment industries; (3) preference was given to companies engaged in local production activities to ensure they were not just distributors; and (4) random selection of the remaining companies. Companies were asked to identify the top three most important training programs before and after workers join the company, and to rate the contribution of these programs to the company’s skills needs. This information was gathered separately for five occupational levels: general workers, operators, technicians, supervisors, and high-level managers.

Second, 18 out of the initial 162 companies were asked to participate in follow-up in-depth interviews. The interviews were semi-structured, combining open questions with Likert-style questions such as “Do you agree with the following statement: Mid-level employees (operator level) with TVET qualifications are able to work faster and with greater accuracy (in comparison to those who have no formal skills training)”. Each company was covered with two interviews, one with the company director or deputy director and one with the head of the HR department. A total of 36 interviews were conducted.

The companies covered in the survey and interviews were based in the coastal region of Southern, Central, and Northern Vietnam, where most of the manufacturing companies are located (see Figure 1).

Figure 1: Provinces (yellow colour) in which data collection took place

Data collected from the survey was encoded and analyzed using descriptive statistical methods. All interview memos were translated from Vietnamese to English, followed by a thematic analysis using NVivo 12.

In terms of the limitations of the analysis, it is important to highlight that the assessment is based on a small number of companies, especially when it comes to the in-depth interviews. Considering the size criterion and the sampling methods used, it is highly probable that all the companies fall within the formal sector of the economy. The analysis is descriptive in nature and focuses on perceptions. While acknowledging these limitations, we still believe that our article can make a relevant contribution given the absence of research in the field.

4 Findings

4.1 Uptake of formal and non-formal TVET

To what extent are formal and non-formal TVET programs used in the Vietnamese manufacturing industry? Some interesting findings emerge from the company interviews (see Figure 1).

Figure 2: The use of formal and non-formal TVET programs in manufacturing industries Note: % of workers who have participated in the respective training; average across the 18 interviewed companies.

About a third of the mid-skilled workers (operators) have undergone formal TVET training before joining their current company. In contrast, this rate increases to more than half for those in higher skilled roles, supervisors, and technicians. For pre-employment TVET programs of a non-formal nature, the participation rates are noticeably higher, reaching 64 percent for mid-skilled employee positions and 68 percent for high-skilled employee positions.

Regarding in-employment training—which includes induction, upskilling, and reskilling initiatives after employment—it is remarkable to observe that nearly all workers participate in induction training and receive additional training at subsequent stages of their employment. This training is predominantly non-formal, conducted either within the company or, to a lesser extent, externally. This finding is consistent for both mid-skilled and high-skilled categories of workers. However, when it comes to external training, there is a pronounced disparity between the two groups. High-skilled workers are significantly more inclined to partake in such training compared to their mid-skilled counterparts.

Even though the sample size of companies interviewed is not large enough to draw definitive conclusions across different industries, it is noteworthy that all the seafood processing and textile companies interviewed unanimously agreed that TVET qualifications are not a prerequisite for hiring operators. According to them, possession of a 9/12 (completion of nine years of compulsory education, including primary and lower secondary school) or 12/12 certificate (completion of the entire 12-year basic education program, encompassing primary, lower secondary, and upper secondary education) suffices. While they acknowledged that having a TVET qualification could be advantageous, it is not considered a compulsory requirement for these positions. These sentiments are clearly echoed in the following excerpts from interviews:

“For operator positions, only a 9/12 certificate and good health are needed. The company does not require them to have a TVET qualification. If they have a TVET qualification, this will be favourable for them and may increase their chances of a promotion.” (VF211)

“For operators, the company does not require them to have a TVET qualification – they will be provided the basic training in the company through the short courses from one to three months to ensure they know the requirements of the company.” (VE15)

“Operator staff must hold at least a lower secondary education certificate, year 9 or above, be in good health, have a height of 1.48m or above, and have writing and speaking skills. If someone had a TVET qualification and experience, this is beneficial but not necessary as they will be trained at the company.” (VG1)

For higher-skills positions such as supervisors, technicians and managers, the formal training programs leading to TVET qualifications are highly valued. All 18 managers interviewed across three manufacturing industries indicated that individuals seeking to apply for or expecting to be promoted to high-skills positions must possess TVET or university qualifications:

“For team leaders and production managers, the company prioritises experience first, followed by TVET qualifications. Before recruiting a candidate to a team leader, the company will conduct an interview and a skills test. For managerial positions, both experience and qualifications are required and compulsory.” (VG3)

“Technicians and supervisors must have the electronics qualification at the advanced diploma or bachelor’s level. Supervisors must have work experience as well.” (VE43)

“For managerial positions, such as the team leaders, the company prefers both a TVET qualifications and experience. These are generally promoted internally and have demonstrated sound experience and ability. They must have the right attitude towards the job and the company. Technicians will be promoted from good technical workers.” (VF38)

In conclusion, the combined quantitative and qualitative data underscore the influence of formal and non-formal training programs extending across various positions and hierarchical levels within manufacturing companies. While there is some flexibility at lower levels regarding the necessity of TVET qualifications, higher positions within these companies overwhelmingly prioritize formal training as a fundamental criterion for recruitment and career advancement. This effect seems to be linked to two main factors: the selection process for enrolling in the trainings and the advantageous outcomes that come with completing them, which will be explored in detail in the following section.

4.2 Contribution to meeting skills needs

Figure 2 illustrates the significant role played by both pre-employment and in-employment training programs in meeting the skill requirements of the manufacturing industry. According to the perspectives of manufacturing company managers, it is evident that these training initiatives have made noteworthy contributions. Remarkably, nearly all managers across the three sectors unanimously agreed that both pre-employment and in-employment TVET programs play a crucial role in fulfilling their industry’s skill requirements, categorizing their impact as either “significant” or “somewhat significant”. When scrutinizing the variation between these two types of programs, it becomes apparent that in-employment programs consistently receive higher ratings compared to pre-employment programs. This discrepancy is strikingly pronounced in the garment industry, while it is noticeably less so in the electronics sector.

Figure 3: Contribution of formal and non-formal TVET programs to meeting skills needs of manufacturing industries. Note: Response to the question “Please assess if the programmes catering to your employees … have contributed to meeting your skills needs”. Pre: Pre-employment / In: In-employment. Information from 162 companies.

Figure 3 further illustrates the impact of pre- and in-employment training programs across different occupational levels. There is a consensus on their valuable contribution across all occupational levels, as captured by the almost 100% of “significant” or “somewhat significant” responses. Notably, pre-employment programs receive distinctly lower evaluations in comparison to in-employment programs, although there is a discernible upward trend in ratings from general worker roles to managerial positions for both types. It is intriguing that pre-employment and in-employment training programs are not seen as interchangeable, but instead appear to complement each other, with their usage rising concurrently across hierarchical occupation levels. A notable exception to this is found with general workers, where no utilization of pre-employment programs was recorded.

Figure 4: Contribution of formal and non-formal TVET programs to meeting skills needs at the occupational levels. Note: Response to the question “Please assess if the programmes catering to your employees … have contributed to meeting your skills needs”. Pre: Pre-employment / In: In-employment. Information from 162 companies.

4.3 Contribution to productivity

In interviews with 36 representatives from 18 manufacturing firms, including human resources and production managers, it was evident that companies perceive employees with formal TVET qualifications to outperform those lacking such formal training. This is true because of a number of factors, including a reduced need for supervision, enhanced problem-solving capabilities, quicker and more precise task execution, and a decrease in errors.

Figure 4 summarizes the responses. A noteworthy 86 percent of company and production managers either strongly agree or agree that individuals with TVET qualifications necessitate less oversight than those without formal training. Few expressed disagreements with this viewpoint. In terms of problem-solving, 100 percent of respondents signaled their strong agreement or agreement, associating this skill with employees holding TVET qualifications. Similarly, 94 percent of managers concurred, either strongly or simply in agreement, that such employees work faster and with more precision. Again, there was little disagreement. In the context of minimizing errors, 86 percent of the respondents acknowledged a connection with formal TVET training.

Figure 5: The contribution of formal TVET programs to productivity. Note: Based on the responses from 18 companies (36 company and production managers).

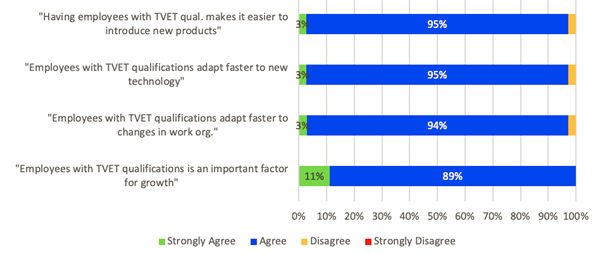

Transformation was prompted in three aspects: “making easier to introduce new product,” “adapting faster to new technology,” and “adapting faster to change in work organization”. Figure 5 illustrates the influence of employees with formal TVET qualifications in terms of these transformation aspects, as well as the growth of manufacturing companies.

A substantial 98 percent of respondents strongly agree or agree that employees with formal TVET qualifications make it “easier to introduce new products”, highlighting their readiness to bolster innovation and new product development in manufacturing sectors. Similarly, the characteristics of “adapting faster to new technology” and “adapting faster to changes in work organization” receive strong agreement or agreement from 98 percent of respondents. This showcases their agility in embracing technological advancements and evolving work setups. Notably, 100 percent of managers agree that employees with TVET qualifications are “an important factor for growth”. This highlights the pivotal role of TVET in driving the growth and expansion of manufacturing industries.

In summary, the findings from Figure 5 emphasize that TVET-qualified employees are seen as invaluable assets to the manufacturing industry, excelling in areas like product innovation, technological adaptation, and organizational flexibility. Moreover, their role in driving industry growth is seen as crucial by all managers. This underscores the value of formal TVET programs in preparing individuals for dynamic and competitive industrial environments.

Figure 6: The contribution of formal TVET to transformation and growth. Note: Based on the responses from 18 companies (36 company and production managers).

Figure 6 provides a comparative analysis of the significance of formal and non-formal TVET programs, as perceived by company managers. Non-formal training, particularly on the job training (OTJ), emerges as highly significant, with 95 percent of respondents expressing strong agreement and agreement. Notably, providing on-the-job training is deemed more valuable than offering formal TVET programs, with a unanimous 100 percent agreement among respondents.

Figure 7: Comparison between formal and non-formal TVET programs Note: Based on the responses from 18 companies (36 company and production managers). OTJ: on the job training.

When examining the adoption of new technology over the past five years, 30 out of 36 companies experienced technology transfer and procured new machinery and equipment. Companies often opted for non-formal TVET programs offered by equipment suppliers instead of involving TVET providers in the technology transfer process. This seems to indicate that TVET providers are not highly regarded when it comes to technology transfer as compared to machinery and equipment suppliers. Existing machinery and technology at TVET providers are often seen as outdated and lagging behind those employed by manufacturing companies.

In summary, the findings from Figure 6 highlight the significance of on-the-job training and practical experiences in the eyes of company managers. Interestingly, the findings from Figures 4 and 5, and from Figure 6 seem to show a contradiction in how companies view TVET. While most companies recognized formal TVET qualifications for their positive impact on productivity, problem-solving, and readiness for innovation, they still favor non-formal TVET programs, particularly on-the-job training. This trend suggests a perception among company managers that non-formal training methods are more practical and relevant to their specific needs. Formal TVET programs often provide general and foundational knowledge and skills, which may not align with the specific requirements of each company. Furthermore, in the context of Vietnam, knowledge and skills taught in these programs may become outdated quickly due to rapid technological advancements, and the introduction of new products and designs in the industry.

“As part of our on boarding process for newcomers, we begin with a comprehensive introduction to our company’s operations. We believe it’s crucial for every team member to gain a deep understanding of our organizational culture before diving into their roles. After this orientation day, we tailor our training programs to each candidate’s unique abilities and the specific requirements of their respective positions. Our approach to training is flexible and designed to maximize the potential of every individual joining our team.” (VE 15 Pr)

Although formal TVET programs may not be the top priority for many managers, possessing a recognized TVET qualification is considered essential for career advancement and promotions. A notable 78 percent of respondents concur on the importance of formal TVET qualifications for professional growth (see Figure 6). This reflects a cultural inclination in Vietnam, where formal qualifications and certifications hold substantial esteem. The emphasis on recognized qualifications suggests a deeply rooted societal value placed on formal education and its symbols.

5 Discussion

The research presented in this article underscores the significant role that in-employment training plays within the manufacturing sector, demonstrating its extensive uptake and the high value placed upon it by companies. The adoption rates of in-employment training are impressive: almost all workers in the electronics, food and beverage, and garment industries undergo induction training and some form of additional upskilling .This makes evident the vital contribution of such training to bridging skills gaps and its precedence over formal TVET programs in the perception of many companies.

Company representatives particularly emphasized the tailored nature of in-employment training, noting its alignment with varied occupational demands, which subsequently results in heightened efficiency and improved productivity across the board. Recognizing the need for continuous learning and skill enhancement in a sector that is constantly evolving, in-employment training is deemed crucial not just for meeting current demands but also for ensuring future growth and competitiveness. This investment in cultivating a workforce that is both skilled and adaptable speaks to the strong commitment from managers. This can be expected to translate into ongoing support and funding for these programs, at least in the mid-sized and large companies of the formal part of the economy which were included in the present study.

In contrast, while formal TVET programs receive positive feedback, they are met with less enthusiasm compared to their non-formal counterparts. Their uptake, especially at lower occupational levels, remains limited. At the same time, however, their value is acknowledged, particularly in terms of facilitating quicker adaptation to workplace demands and contributing to industry growth. The analysis indicates that formal TVET programs also play a role in career advancement, potentially influenced by the cultural premium placed on education in Vietnam. This may create a dynamic where employees with formal qualifications are more likely to be placed in positions of leadership. A signaling effect of these programs might also be important, where the perceived value of the training is increased through the selection of its participants.

The inadequacies of the formal TVET system, from underdeveloped facilities and equipment to a lack of necessary resources, have led to a shift towards more non-formal training programs. These are partly provided by companies involved in technology transfer and equipment supply, creating a competitive advantage over traditional TVET providers.

It would, however, be an oversimplification to frame this as a case of straightforward competition between formal and non-formal training. Each has its unique role to play, with formal training potentially better suited for the development of foundational and generic skills, which can aid in both educational progression and labor market mobility. Despite this, there is a clear and urgent need for the formal TVET system to assimilate some of the successful aspects of non-formal training, particularly in terms of its relevance to the labor market.

The research further reveals that substantial segments of the workforce are currently excluded from foundational vocational training, which could impede their future mobility and progression, especially in a context where qualifications play a critical role in promotion decisions. Addressing this gap and ensuring access to foundational training for all levels of the workforce is a vital step towards building a more inclusive and equitable training ecosystem, positioning the manufacturing sector in Vietnam for sustained success and resilience.

Acknowledgments

The research leading to this article has been jointly funded by the Swiss National Science Foundation (SNSF) and the Swiss Agency for Development and Cooperation (SDC), through their joint research program “R4D”, under the call “Employment” (SNSF grant number 400340_194006).

The authors extend a special thanks to Ha-My Nguyen and Michael Morlok for their valuable assistance in editing our work.

References

Asian Development Bank (ADB). (2020). Vietnam Technical and Vocational Education and Training Sector Assessment. Manila: ADB. Online:

https://www.adb.org/sites/default/files/institutional-document/551001/viet-nam-tvet-sector-assessment.pdf (retrieved 21.01.2024).

Asiyai, R. (2018). Exploring the Contributions of Non-Formal Education to the Development of Human Capital in Southern Nigeria. In: Sokoto Educational Review, 18, 1.

Booth, A. L. & Snower, D. J. (1996). Acquiring Skills: Market failures, their symptoms and policy responses. New York: Cambridge University Press.

Crouch, C., Finegold, D., & Sako, M. (1999). Are skills the answer?: the political economy of skill creation in advanced industrial countries. Oxford: Oxford University Press.

Dang, V. H. & Nguyen, T. T. (2023). Designing a model of strategic partnership between the vocational skills development system and industry: case study in Vietnam. In: TVET@ Asia, issue 21, 1-19. Online: https://tvet-online.asia/21/designing-a-model-of-strategic-partnership-between-the-vocational-skills-development-system-and-industry-case-study-in-vietnam/ (retrieved 01.08.2023).

Finegold, D. (1996). Market Failure and Government failure in Skills Investment. In Booth, A.L. et al. (eds.): Acquiring Skills: Market failures, their symptoms and policy responses. New York: Cambridge University Press, 235-253.

Kanapathipillai, K. & Azam, S. (2020). The Impact of Employee Training Programs on Job Performance and Job Satisfaction in the Telecommunication Companies in Malaysia. In: European Journal of Human Resource Management Studies, 4, 3.

Kominarets, T., Fomin, V., Bieloliptseva, O., Tkachenko, M., Malykhin, A., & Pryshliak, O. (2022). Strategic Tasks of Contemporary Education: Formal, Nonformal, Informal. In: Revista Românească pentru Educaţie Multidimensională, 14, 4, 394-407.

MacDonald, S., Nink, C., & Stephen Duggan, S. (2010). Building better formal TVET systems: principles and practice in low- and middle- income countries. Online: https://www.mtctrains.com/wp-content/uploads/2017/06/Principles-and-Strategies-of-a-Successful-TVET-Program.pdf (retrieved 21.01.2024).

Mawer, G. & Jackson, E. (2005). Training of existing workers: Issues, incentives and models. Adelaide: NCVER.Online:

https://ncver.edu.au/__data/assets/file/0014/5144/nr3017.pdf (retrieved 22.01.2024).

Misko, J. (2008). Combining formal non-formal and informal learning for workforce skill development. Online:

https://files.eric.ed.gov/fulltext/ED503360.pdf (retrieved 21.01.2024).

Organisation for Economic Co-operation and Development (OECD). (2023). Recognition of Non-formal and Informal Learning – Home. Online:

https://www.oecd.org/education/skills-beyond-school/recognitionofnon-formalandinformallearning-home.htm(retrieved 22.01.2024).

Richardson, S. (2004). Employers’ contribution to training. Adelaide: NCVER. Online: https://ncver.edu.au/__data/assets/file/0021/4467/nr1005.pdf (retrieved 22.01.2024).